General Technical Bulletin

General Technical Bulletin

When to Replace a Biosafety Cabinet

Biological Safety Cabinets (BSCs) are essential for maintaining a safe working environment in laboratories protecting personnel and products from exposure to harmful agents. Modern BSCs have a recommended usable life of 15 years. BSCs manufactured in the 1970s to early 1990s have typically provided over 20 years of service but may now require extensive maintenance or replacement due to technological advancements and regulatory changes.

Factors to consider when replacing BSCs include the availability of replacement parts, as older models may no longer support current HEPA filters, blowers, motors, and electrical systems due to changes in manufacturing standards. For instance, magnetic ballasts and T12 fluorescent bulbs used in older BSCs have no longer been available since 2010.

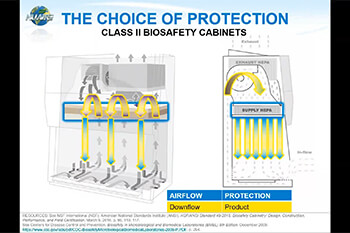

Since the 1992 revision of the NSF Standard 49, significant improvements have been made in BSC design, including enhanced safety containment performance, ergonomic features, and energy efficiency. Newer models undergo rigorous testing for inflow velocity, motor/blower performance, and biological safety containment performance, ensuring higher safety standards.

Modern BSCs also feature ergonomic improvements such as increased work area, forearm support, expanded vision zone, and optimal posture adjustments. These changes reduce user fatigue and improve overall productivity.

Regarding energy efficiency, the introduction of Direct Current (DC) Electronically Commutated Motors (ECMs) in 2009 marked a significant upgrade from traditional AC motors. ECMs consume 50% less energy, offer improved performance and capacity, and automatically compensate for filter loading. Additionally, lighting systems have transitioned to electronic ballasts and T8 fluorescent or LED bulbs, providing further energy savings.

Institutes should consult their Environmental Health and Safety Department, an Accredited Certifier, NuAire Sales Representatives, or the NuAire Technical Service Department for guidance on repairing or replacing their BSCs. NuAire supports older models as long as replacement parts are available from vendors.