Custom Lab Equipment for Your Unique Needs

Innovation doesn’t have standard dimensions—so your biosafety enclosure shouldn’t either. NuAire creates purpose-built containment and clean airflow solutions engineered around your workflow, not the other way around.

Why Choose Custom Solutions

Built for Your Process

Protection Doesn’t Have Standard Dimensions

Built for Automation

Optimized for People

Comfort, Containment, and Customization

Custom Capabilities with Proven Quality

Our Customization Process

Learn about out four-step process for creating your custom solution.

Consultation

We begin by listening. You’ll share your application details, workflow requirements, and any must-have features for your custom enclosure.

Design & Engineering

Our engineers translate your needs into a tailored solution—complete with detailed drawings for your review and approval.

Manufacturing & Testing

Once approved, we build your enclosure to spec and perform any necessary performance and safety testing.

Delivery & Installation

We coordinate delivery and ensure that your cabinet—whether assembled or modular—is installed efficiently in your facility.

Take a Closer at Our Process

Watch our process of creating a custom biosafety cabinet, from collaborative design with engineers to drafting and final client approval.

Your Customization Experts

Collaborating with you to build the perfect solution

Bryan Krivo

Custom Products Engineering Lead

Leads custom engineering with 7 years of experience, delivering tailored containment solutions through precision, collaboration, and a strong focus on meeting each client’s unique technical requirements.

Damian Kurtz

Custom Products Sales

With 7+ years at NuAire, transitioned from building A2 cabinets to service and sales. Specialized in centrifuges, freezers, and South American support, now leveraging full product lifecycle knowledge to drive custom solutions and customer success.

What Makes a Unit "Custom"?

Beyond the Standard Model

Configured outside catalog specs to meet your lab’s exact application.

Built-In Features Your Way

Add monitor cutouts, outlets, pass-throughs, or microscope windows.

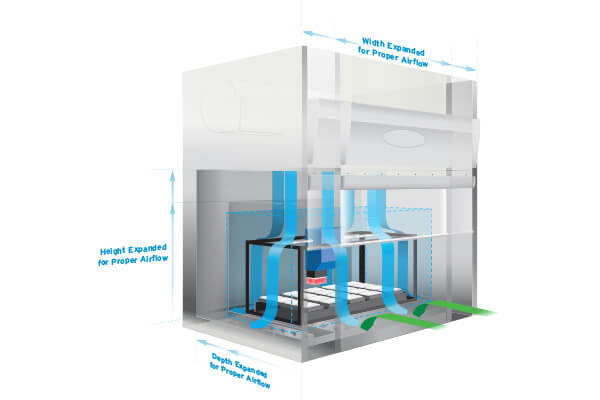

Custom Cabinet Dimensions

Width, depth, or height adjusted for your equipment and airflow needs.

Lab Tools, Integrated Seamlessly

Designed to house liquid handlers, robotic arms, weight scales, and precision tools.

Materials Fit for the Mission

Choose 316 SST, lead lining, or cleanable finishes for critical workflows.

Strength Where You Need It

Reinforced work surfaces and isolation-ready designs for heavy loads.

Scientific Industries

Nuaire is Ready For All your Needs

Industries

Biomedical / Microbiological

NuAire customizes Class II biosafety cabinets to meet specific microbiological research needs, optimizing airflow, containment, and cleanability for sensitive assays, infectious agents, and variable laboratory setups.

Industries

Vivarium Animal Laboratory

NuAire designs tailored biosafety cabinets and transfer stations for vivarium workflows, integrating features like deep wells, feed hoppers, and waste chutes to support cage changing and animal handling with comfort, safety, and containment.

Industries

Clean Rooms and Pharmacy

For USP <797>/<800> compliance, NuAire builds cleanroom-ready C-PECs with stainless steel surfaces, integrated monitors, and camera mounts to improve documentation, cleanability, and workflow for compounding sterile and hazardous drugs.

Industries

Pharmaceuticals

NuAire develops custom enclosures for drug development and GMP manufacturing, with full stainless steel builds, expanded interiors, and monitoring ports to support air quality tracking, equipment fit, and high-throughput R&D or QC.

Applications

Drug Discovery

Custom biosafety cabinets from NuAire support drug discovery with isokinetic probe holders, particle counters, and optimized airflow to maintain clean conditions around delicate, high-value research instruments and assays.

Applications

Robotics

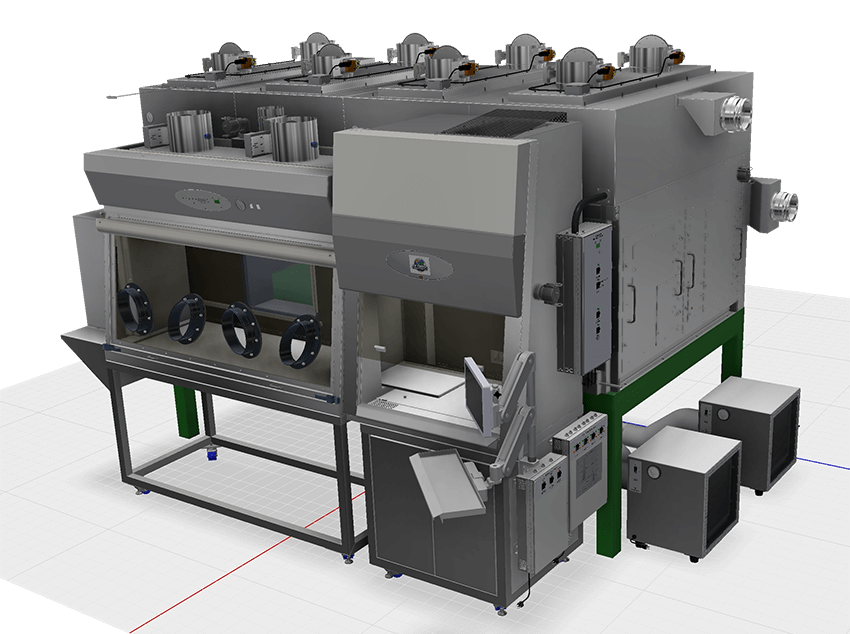

NuAire engineers room-sized containment systems for robotics, including large-access doors and roll-in platforms. These systems maintain Class II airflow protection around large automated equipment used in pharma and research labs.

Applications

Lab Automation

NuAire creates automation-ready cabinets with reinforced work surfaces, cord pass-throughs, and hinged windows—ensuring proper airflow, easy device integration, and safe operation for large robotic and liquid handling systems.

Industries

Academic & Research Laboratories

NuAire provides tailored containment solutions for universities and research institutions, designing flexible biosafety cabinets that adapt to evolving study needs, multi-user labs, and specialized research equipment in shared environments.

Explore What's Possible with NuAire Custom Solutions

From modifying airflow systems to fully bespoke cabinetry, NuAire delivers precision-engineered products that adapt to your team’s needs. Explore our Custom Solutions Lookbook to see how we collaborate with researchers, safety officers, and facility planners to bring custom laboratory visions to life — all backed by certified safety standards and lifetime support.

Resources

View All Resources

White Paper

White Paper

Building a Custom Biosafety Cabinet

Learn when and why labs need a custom biosafety cabinet. Explore key design, placement, and certification steps to safely contain large or complex automation equipment.

White Paper

White Paper

The Importance of Lab Equipment Configurability

Discover how configurable lab equipment optimizes workflow, safety, and investment for research labs. Learn why flexibility matters most in modern scientific environments.

Flyer

Flyer

Custom Biosafety Cabinets for the Automated Laboratory

Discover NuAire's custom biosafety cabinets designed for the automated laboratory. Learn how tailored solutions ensure safety and optimal airflow for advanced lab automation equipment.

Flyer

Flyer

Custom Biosafety Cabinets for Lab Automation and Drug Discovery

Discover NuAire's custom-built biosafety cabinets for lab automation and drug discovery, featuring advanced materials and tailored features for optimal performance and cleanliness.

Webinar

Webinar

Customizing Biosafety Cabinets A Holistic Approach

Learn from top experts how to effectively customize biosafety cabinets for your lab, covering everything from design and risk assessment to long-term maintenance, in our upcoming webinar, Customizing Biosafety Cabinets: A Holistic Approach.

White Paper

White Paper

Custom Biosafety Cabinets for Robotics and Automation - Sanofi Case Study

This short case study details how NuAire engineers worked directly with a French pharmaceutical company, Sanofi, to fabricate a fully customized Biosafety Cabinet to house their automated liquid handlers.

White Paper

White Paper

Building a Custom Biosafety Cabinet for Lab Automation | NuAire White Paper

Learn when and why labs need a custom biosafety cabinet. Explore key design, placement, and certification steps to safely contain large or complex automation equipment.

White Paper

White Paper

Why Lab Equipment Configurability Matters | NuAire

Discover how configurable lab equipment optimizes workflow, safety, and investment for research labs. Learn why flexibility matters most in modern scientific environments.

Flyer

Flyer

Custom Biosafety Cabinets for the Automated Laboratory | NuAire

Discover NuAire's custom biosafety cabinets designed for the automated laboratory. Learn how tailored solutions ensure safety and optimal airflow for advanced lab automation equipment.

Flyer

Flyer

Lab Automation & Drug Discovery Biosafety Cabinets | NuAire

Discover NuAire's custom-built biosafety cabinets for lab automation and drug discovery, featuring advanced materials and tailored features for optimal performance and cleanliness.

Webinar

Webinar

Customizing Biosafety Cabinets A Holistic Approach | NuAire

Learn from top experts how to effectively customize biosafety cabinets for your lab, covering everything from design and risk assessment to long-term maintenance, in our upcoming webinar, Customizing Biosafety Cabinets: A Holistic Approach.

White Paper

White Paper

Sanofi Custom Biosafety Cabinet for Robotics | NuAire

This short case study details how NuAire engineers worked directly with a French pharmaceutical company, Sanofi, to fabricate a fully customized Biosafety Cabinet to house their automated liquid handlers.

FAQ Customs

Why choose a custom biosafety cabinet instead of a standard one?

Standard cabinets often fail to accommodate large or complex automation equipment. Custom NuAire cabinets are engineered to fit specific workflows, ensuring optimal airflow performance and safety by eliminating turbulence caused by oversized or obstructive instruments.

How does NuAire ensure safety in custom designs?

NuAire custom cabinets comply with NSF/ANSI 49 standards for containment and safety. Designs undergo rigorous airflow validation, and custom units can include smoke visualization tests to ensure airflow is not compromised by the client's equipment.

Can custom biosafety cabinets fit through standard doorways?

Yes. NuAire's engineers take delivery and installation into account, designing modular or multi-piece cabinets that can fit through standard lab doorways, helping avoid costly construction changes.

What equipment can be integrated inside NuAire’s custom cabinets?

Custom cabinets can house:

- Robotic liquid handlers

- TPN compounders

- Cell culture systems

- High-throughput screening platforms

- Analytical instruments

Features like reinforced work surfaces, cord pass-throughs, and hinged windows ensure mechanical and functional compatibility.

What material options are available?

Work zones and exterior panels are typically constructed from Type 316 stainless steel for corrosion resistance and cleanability. Other material options may be used based on environmental or chemical compatibility.

Can NuAire perform airflow validation with the customer’s equipment installed?

Yes. NuAire offers airflow smoke visualization testing with your equipment in place. This helps in meeting field certification standards and assures proper airflow is maintained post-installation.

Are NuAire custom BSCs compliant with GMP and global standards?

NuAire custom biosafety cabinets are designed to meet the requirements of regulatory frameworks such as EU GMP Annex 1, ISO 14644, and NSF/ANSI 49, but NuAire does not hold these certifications on behalf of the end user or facility. It is the responsibility of the end user to validate the cabinet within their qualified environment to ensure full compliance. However, NuAire supports this process by providing documentation, airflow testing, and design features that facilitate regulatory alignment.

How does the custom design process work?

The process includes:

- NDA for proprietary info

- Engineering interviews

- Iterative CAD model development

- Customer sign-off

- Manufacturing in NuAire’s Minnesota facility

This collaborative method ensures the solution fits both workflow and compliance needs.

Can NuAire provide a custom solution for pharmaceutical or OEM partners?

Yes. NuAire designs OEM-compatible solutions tailored for seamless integration with existing systems, such as automated drug compounding or assay prep platforms.

What are the lead times for custom solutions?

Lead times vary based on project complexity but typically range from 10 to 26 weeks. NuAire’s custom product team helps expedite timelines through early collaboration and in-house engineering expertise.

Request a Quote for Custom Products.

Thank you for completing the form.

We will be in touch. If you have any urgent questions, please reach out at 763-553-1270