White Paper

White Paper

Building a Custom Biosafety Cabinet

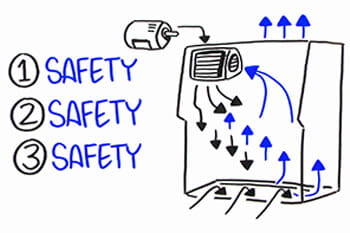

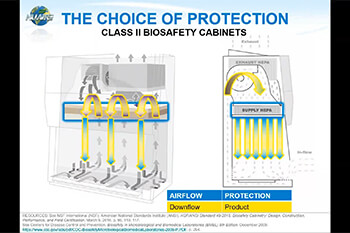

This white paper explains how to design a custom biosafety cabinet (BSC) when standard models cannot safely contain large or complex lab automation equipment —such as 3D bioprinters, automated liquid handlers, or robotics. It outlines how to perform a risk assessment, develop design requirements, plan for installation, and ensure the system can be field certified.

When Do You Need a Custom Biosafety Cabinet?

A custom BSC is required when standard Class II cabinets cannot accommodate the footprint, height, movement, or workflow of your instrument. Labs using advanced automation platforms or integrated robotic systems may require specialized containment solutions that maintain personnel, product, and environmental protection.

- Equipment that exceeds standard BSC dimensions

- Processes that generate aerosols or splashes

- Automation that requires unique airflow patterns

- Workflows needing specialized access, pass-throughs, or integration with adjacent devices

- Regulatory or biosafety requirements not supported by off-the-shelf cabinets

For a broader overview of how automation influences cabinet design, explore our webinar Customizing Biosafety Cabinets: A Holistic Approach.

Key Design Considerations

Designing a custom BSC begins with a formal risk assessment conducted with your biosafety officer, principal investigators, facilities team, and the automation vendor. Important considerations include:

- Equipment dimensions, motion envelope, and service clearances

- Sensitivity to vibration, airflow, or temperature

- Electrical and utility requirements (power, data, compressed air, gases)

- Access doors, glove ports, and viewing windows to support workflow

- Operator ergonomics and daily use

- Maintenance access and future serviceability

- Routing for cables and consumables without compromising containment

For an example of how leading organizations approach BSC customization for robotics, see the Sanofi case study: Custom Biosafety Cabinets for Robotic Automation.

Placement and Installation

Where the custom BSC is positioned significantly affects performance. This white paper details how to evaluate:

- Room airflow patterns

- Traffic flow and proximity to doors or diffusers

- Service clearance on all sides

- Potential impact from nearby hoods, equipment, or HVAC turbulence

- Noise, vibration, and user comfort

Proper placement ensures the cabinet can be delivered, installed, and validated without disruption to the lab—especially when working with larger or more complex automation systems.

Performance Testing & Field Certification

A custom BSC must be able to pass NSF/ANSI 49–aligned performance tests with the equipment installed. The white paper explains:

- Why early engagement with a field certifier prevents design roadblocks

- Which tests are required for custom units

- How airflow and containment testing is conducted with automation inside the cabinet

- What documentation is needed for compliance and ongoing maintenance

Who Should Read This White Paper?

This guide is designed for:

- Lab managers

- Project managers

- Biosafety & EHS officers

- Facilities and engineering teams

- Automation equipment vendors

It provides a shared framework so all stakeholders can collaborate effectively during design and installation—especially when adopting new lab automation technologies.