Infographic

Infographic

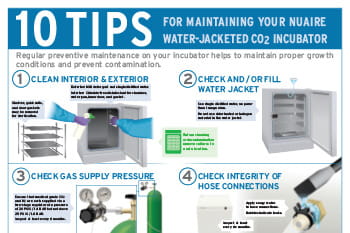

10 Tips for Maintaining Your NuAire Water-Jacketed CO₂ Incubator

Proper maintenance is essential to ensuring safe, reliable, and consistent cell culture conditions. NuAire’s 10 Tips for Maintaining Your Water-Jacketed CO₂ Incubator poster provides clear, step-by-step guidance to help your team prevent contamination, sustain performance, and extend equipment life. The poster distills best practices for cleaning, water quality, leak checks, filter replacement, calibration, and condensation control—so your incubator stays ready for critical research.

What You’ll Learn

- Cleaning procedures: Use a mild detergent with single-distilled water for exterior surfaces, and a chloride-free disinfectant for the chamber, water pan, inner door, and gaskets. Shelves, guide rails, and door gaskets can be removed for sterilization. Always relocate cultures to a safe location before cleaning.

- Water-jacket care: Fill with single-distilled water no purer than 1 mega-ohm. Do not use chlorinated or halogen materials in the water jacket.

- Gas supply standards: Use medical-grade CO₂ and N₂ with two-stage regulators at 20 PSIG / 1.4 BAR, and never exceed 25 PSIG / 1.8 BAR.

- Leak checks: Apply soapy water to hose connections—bubbles indicate leaks. Include this test in your six-month inspection routine.

- External filters: Inspect CO₂, N₂, and air disk filters behind the bottom front valence at least every six months. Replace when visibly discolored or after every fifth CO₂ tank.

- Sensor bay filters: Replace the wet disk filter when discolored, and the capsule HEPA filter when discolored or after four years of use.

- Door seals: Ensure inner and outer door gaskets are free of cracks and wear. Inspect at least every six months.

- Water pan: Refill weekly with single-distilled water (+/- 1 mega-ohm) to support proper humidity levels and prevent contamination.

- Calibration: Calibrate temperature, CO₂, RH, and O₂ sensors according to your laboratory’s standard operating procedures and quality schedule.

- Condensation control: Adjust the door heater to eliminate excess condensation. If condensation persists, contact NuAire Service for guidance on chamber air injection adjustments.

Display this poster in your lab as a quick visual reminder to maintain optimal growth conditions and reduce contamination risks—helping protect your team and your research.