Article

Article

How Does a Class III Biological Safety Cabinets Work?

Class III Biosafety Cabinet Overview

Purpose, Containment Design, and Material Transfer

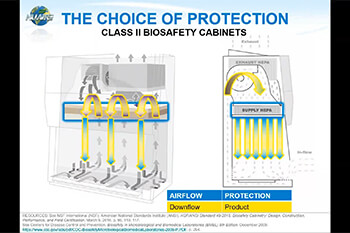

The Class III biological safety cabinet was designed for work with biosafety level 4 (BSL-4) microbiological agents, and provides maximum protection to the environment and the worker. It is a gas-tight enclosure with a non-opening, completely sealed, viewing window. Access to the interior of the cabinet is through a double-door pass-through interchange box (such as an autoclave) that can be decontaminated between uses and/or a dunk tank that is accessible through the cabinet floor into the floor of a Class I or Class II cabinet. Reversing that process allows for safe removal of materials from the Class III biosafety cabinet. Class III cabinets represent the highest level of containment in the suite of biosafety cabinet classes, providing personnel, environmental, and product protection consistent with advanced biosafety programs.

Air Handling and Filtration Requirements

Both supply and exhaust air are HEPA filtered. Exhaust air must pass through two HEPA filters, or a HEPA filter and an air incinerator, before discharge to the outdoors. Airflow is maintained by a dedicated independent exhaust system exterior to the cabinet, which keeps the cabinet and all associated ducting under negative pressure (usually about 0.5 inches of water pressure). This ensures that contaminated air cannot escape the containment enclosure and that proper directional airflow is preserved. Routine certification and performance testing help confirm that filtration and negative pressure systems continue to meet design standards such as NSF/ANSI 49.

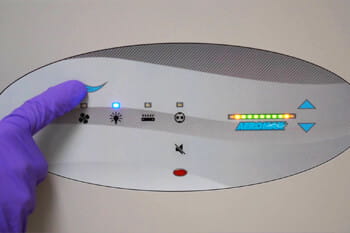

Operator Interface, Workzone Airflow, and Installation Considerations

Long, heavy-duty rubber gloves are attached in a gas-tight manner to ports in the cabinet and should permit replacement without compromising containment. Although these gloves restrict movement for the manipulation of the materials isolated inside the cabinet, they prevent the user’s direct contact with hazardous materials. The trade-off is clearly on the side of maximizing personal safety.

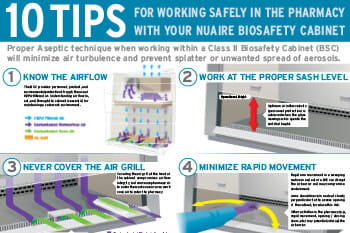

Depending on the design of the cabinet, the supply HEPA filter provides particulate-free, somewhat turbulent airflow within the work environment. To minimize interior turbulence, the inflow air should be ducted to a distribution manifold located on the rear wall just above the work surface. The distribution manifold also provides the means to house an anti-static bar, bathing plastic materials with both positive and negative ions.

Several Class III cabinets can be joined together in a “line” to provide a larger work area. Such cabinet lines are custom-built; the equipment installed within the cabinet line (e.g., refrigerators, small elevators, shelves to hold small animal cage racks, microscopes, centrifuges, incubators, etc.) is generally custom-built as well. Furthermore, Class III cabinets are usually only installed in maximum containment laboratories that have controlled access and require special ventilation or other support systems (such as steam for autoclaves). The reader should consult more definitive literature on these systems.