Drawing

Drawing

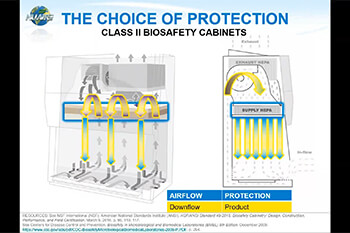

Class II, Type B2 Biosafety Cabinet Airflow Schematic

A total exhaust Class II, Type B2 Biosafety Cabinet (BSC) is designed to provide personnel, product, and environmental protection using HEPA-filtered air. The airflow pattern in a total exhaust Class II, Type B2 Biosafety Cabinet is designed to draw air from the laboratory continuously, filter it through a HEPA filter, and exhaust it outside the laboratory through a dedicated facility exhaust system to prevent the release of potentially hazardous materials.

The airflow pattern in a total exhaust Class II, Type B2 Biosafety Cabinet typically works as follows:

Exhaust Track:

- A roof-mounted exhaust fan creates the inflow at the front of the cabinet.

- Air is drawn into the front and back grill and around the side of the work surface.

- Air is pulled up the back plenum into the dedicated exhaust path.

- Air passes through an Exhaust HEPA filter before it enters the ductwork and is dispersed through a roof-mounted fan.

Supply Track:

- Supply air is drawn into the top of the cabinet through a motor/blower.

- Supply air is pushed through a Supply HEPA filter creating unidirectional downflow air in the work zone.

- The dedicated exhaust system pulls the supply air that splits at the center of the work zone through the front and back grills.

It is important to note that the performance of the BSC depends on the motor/blower and facility exhaust system working in harmony. Therefore, regular maintenance and monitoring of the airflow performance are necessary to ensure that the cabinet works appropriately and provides the required level of protection.