Video

Video

Working Safely in Your Containment Ventilated Enclosure

NuAire, a Kewaunee company, designed this training video to help your team work confidently and safely inside a Containment Ventilated Enclosure (CVE) during non-sterile hazardous drug compounding. The demonstration walks through PPE, workflow, powder handling, and cleaning techniques that reduce exposure risk for personnel, patients, and the environment.

What this Containment Ventilated Enclosure training covers

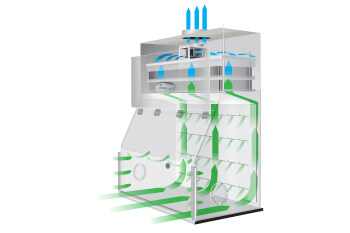

“Working Safely in Your Containment Ventilated Enclosure” follows a technician through a complete compounding cycle in a negative-pressure CVE. You’ll see how proper preparation, airflow-aware technique, and disciplined cleaning practices work together to prevent aerosolized powders from leaving the work zone.

The video is especially useful for pharmacy technicians, lab managers, safety officers, and project managers responsible for USP-compliant non-sterile hazardous drug workflows and training.

Before you begin: training, access, and PPE

Only properly trained personnel involved in preparing and dispensing compounded preparations should work in the CVE or enter the compounding area. Your facility’s standard operating procedures and applicable USP requirements for non-sterile preparations should define the minimum personal protective equipment (PPE) to be worn at all times.

Typical PPE for hazardous drug powder handling may include:

- Facial hair covering (if applicable)

- Mask or respirator as defined by facility policy

- Hair bouffant or head cover

- Shoe covers

- Appropriate gowning and double gloving per SOPs

Personnel must perform proper hand hygiene when entering the compounding area. This includes washing hands with soap and water for at least 30 seconds, drying with disposable towels, and allowing hands to dry completely before donning gloves.

Pre-staging materials in the CVE

A key safety principle is to minimize the need to move hands in and out of the CVE once powder handling begins. The video demonstrates how to:

- Review the compounding preparation and identify all materials needed for the full procedure

- Place chemicals, utensils, glassware, wipes, and other tools inside the CVE before starting manipulation

- Position items to support a front-to-back workflow that aligns with the CVE’s airflow pattern

By thoroughly pre-staging materials, the technician avoids unnecessary interruptions, maintains containment, and reduces the chance of contaminating gloves or external surfaces.

Designing the workflow around containment

As part of the pre-staging method, the video shows how to set up a “wet bin” just outside the CVE face opening. Soiled glassware and utensils are transferred directly into this bin for transport to the sink, helping to keep powders wet and contained during cleaning.

When compounding formulation software is used, the infrared scanner is positioned outside the CVE while the computer mouse remains inside the work zone. This allows the technician to:

- Scan containers and document steps without breaking containment

- Keep hands inside the CVE for every step of the workflow

- Maintain consistent airflow and reduce arm movement through the access opening

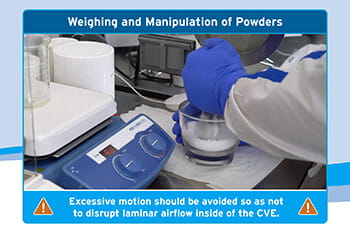

Maintaining airflow and technique inside the CVE

To maintain laminar airflow inside the CVE, the technician uses slow, deliberate, and intentional movements when weighing and manipulating powders on the analytical balance. Excessive or rapid motion can disrupt the airflow pattern, which increases the risk of powder escape or cross-contamination.

Best practices include:

- Working from clean to dirty, front to back, in alignment with airflow

- Keeping large objects from blocking critical air paths

- Avoiding sweeping motions that could push powders toward the access opening

Using the waste chute and wet-transfer methods

The CVE in the video is equipped with a waste chute mounted on the side of the work zone. The chute allows the technician to dispose of contaminated wipes, used gloves, and other waste without opening the viewing window or disrupting airflow.

Glassware and utensils that have contacted powders are handled carefully before removal from the CVE. A “wet-to-wet” transfer method is used:

- Powder-contaminated surfaces are sprayed or wiped while still inside the CVE

- Liquids help keep micronized powders from becoming airborne

- Items are moved directly into the wet bin for transport to the sink

Because micronized powders can hold a static charge on plastic containers, the technician also wipes down bottles to remove any residual powder before taking them out of the enclosure.

Glove changes and waste handling

The outer layer of gloves worn during active powder manipulation becomes contaminated and should not be used for subsequent cleaning or material transport. Before removing chemical containers or glassware from the CVE, the technician:

- Doffs the outer layer of gloves

- Places used gloves into the CVE’s waste chute

- Ensures only clean inner gloves contact decontaminated items

When returning to the CVE for final cleaning, a new outer pair of gloves is donned. These gloves will become soiled during the cleaning process and should be discarded into the waste chute at the end of the procedure.

Cleaning the CVE from front to back

Proper cleaning of a negative-pressure CVE is designed to keep particulates under control and within the airflow. The video demonstrates how:

- The technician wipes surfaces in the direction of airflow (front to back)

- The wiper is reoriented after each pass to expose a clean face

- All soiled wipes and cleaning materials are disposed of via the waste chute

This method maximizes absorption and cleaning efficiency while using the CVE’s laminar airflow to move airborne particulates safely toward the exhaust.

Removing the waste bag safely

At the end of a shift, or when the waste bag is nearly full, the technician removes the bag in a way that prevents particulates from escaping into the room:

- Twist and hold the neck of the bag while slowly sliding it off the waste chute collar

- Maintain control of the bag opening until it is fully off the chute

- Tie a secure knot in the twisted neck of the bag so no powders can be released

This final step helps protect personnel, housekeeping staff, and the surrounding environment from residual hazardous drug contamination.

Who should watch this CVE safety video?

This resource is designed for:

- Pharmacy technicians and compounding staff

- Lab managers and project managers responsible for daily operations

- Safety officers and biosafety professionals developing or reviewing SOPs

- Facilities, engineering, and pharmacy leadership planning new CVE installations

By reinforcing best practices for PPE, staging, technique, and cleaning, the video supports a safer, more consistent, and more compliant compounding environment in any facility using a Containment Ventilated Enclosure.