Article

Article

How Does a Class I Biosafety Cabinet Work?

Class I Biosafety Cabinet Overview

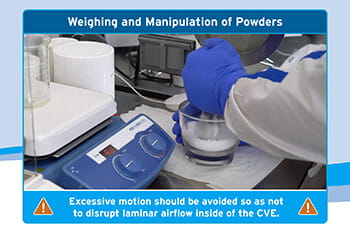

The Class I Biosafety Cabinet (BSC), also referred to as a Biological Safety Cabinet or Class I Containment Ventilated Enclosure (CVE), provides personnel and environmental protection, but no product protection.

Protection Type and Common Use Cases

It is similar in air movement to a chemical fume hood but has a limited fixed work access opening, and the exhaust air must be HEPA filtered to protect the environment. The Class I BSC is designed for general microbiological research with low and moderate-risk agents or non-sterile hazardous drug compounding in the pharmacy. Also, the work zone, which is typically much smaller than a chemical fume hood, is geared to working with biologicals whose process/procedures dictate the use of moderate amounts of volatile liquids that are not suitable for recirculating cabinets or hazardous drugs such as powders used during the compounding of hormone therapy.

Airflow Path and Inflow Velocity Requirements

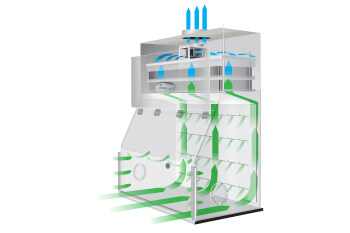

The Class I BSC is similar to a standard chemical fume hood, in that unfiltered room air is drawn through an access opening, which provides personnel protection, then across the work surface, through an exhaust plenum, and out the top. However, to be classified as a Class I BSC, the inward flow of air must be maintained at a minimum inflow velocity of 75 linear feet per minute (FPM) (0.38 m/s) through the front access opening. The access opening design should be following accepted design procedures for fume hoods, such as airfoils, exterior lighting, and properly designed interior baffles to minimize interior roll, etc.

Exhaust/Recirculation Configurations and Building Exhaust Interlocks

Some Class I BSCs are equipped with an integral exhaust blower. The Class I cabinet may be recirculated back into the laboratory environment if no volatile chemicals are present. A Class I CVE may be recirculated back into the pharmacy if exhausted air passes through redundant (two) HEPA filters as per USP 797 and USP 800. If the Class I BSC is connected to a facility’s exhaust system, the cabinet's blower must be interlocked with the building exhaust fan. If the building exhaust fan fails, the cabinet's exhaust blower must be turned off to avoid pressurizing the exhaust ducts.

HEPA filter(s) should be installed on the fan's outlet side, as shown, to allow easy integrity testing. It is good design practice to surround all contaminated positive pressure plenums with a vacuum to preclude plenum leaks from escaping the cabinet into the laboratory. If the ducts are pressurized and the HEPA filter develops a leak, contaminated air could be discharged into other parts of the building or the environment.