Video

Video

Proper Preparation - The 4 Steps to Take Before You Begin Work in Your Biosafety Cabinet

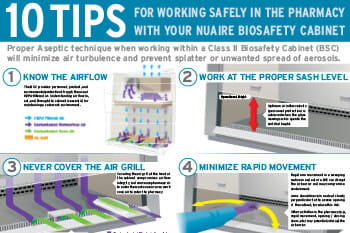

The 4 Steps to Take Before You Begin Work in Your Biosafety Cabinet provides essential guidelines for lab personnel to safely and effectively prepare their biosafety cabinet (BSC) for work. Ensuring a clean and safe environment is critical in any laboratory setting, and this video outlines vital steps to achieve that.

Each laboratory should have a biosafety operations manual identifying potential hazards and specifying practices and procedures to minimize or eliminate risks. Proper training for laboratory personnel is crucial. They must understand the potential hazards, necessary precautions, and how to respond to exposures. The laboratory director should establish policies to ensure that only those advised of the potential hazards and who meet specific entry requirements, such as immunization, can enter the laboratory or animal rooms.

To safely turn on your BSC, the cabinet blowers should be operated for at least three to five minutes before beginning work to purge any particulates in the cabinet. Ensure the work surface, interior walls, and window surfaces are disinfected. While ultraviolet lamps can help, they should not be solely relied on for a clean work area. Disinfect the surfaces of all materials and containers placed into the cabinet to reduce the introduction of mold spores and minimize contamination.

A written checklist of materials necessary for a particular activity is vital. Place everything needed to complete your job inside the cabinet before beginning work to minimize arm movement disruptions across the fragile air barrier. Physical activity in the lab should be kept to a minimum to avoid disturbing the cabinet's airflow.

Ensure the air intake to your BSC is unobstructed. Remove any items on the intake grills that might block or disrupt the air supply. Place all materials back in the cabinet as possible while keeping them within reach, and position aerosol-generating equipment toward the rear to take advantage of the air split.

Before working with materials inside the cabinet, wait at least one minute to allow the cabinet to stabilize and air to sweep contaminants from hands and arms. Only materials and equipment required for immediate work should be placed in the cabinet. Use horizontal pipette discard trays with an appropriate chemical disinfectant and avoid using upright pipette collection containers.

Proper dress is essential for protection. Wear lab coats buttoned over street clothing, protective eyewear, and latex or nitrile gloves when handling cultures or contaminated surfaces. Decontaminate laboratory equipment and work surfaces routinely, especially after work with infectious materials and after spills, splashes, or contamination.

By following these steps, laboratory personnel can ensure the safety and effectiveness of their biosafety cabinet, protecting themselves, their work, and the environment.