Article

Article

Fume Hood vs Biosafety Cabinet

Using the wrong device (e.g., a Biosafety cabinet for solvents) can increase exposure risk. Below, we explain how each works, what each protects, and when to use which—updated for NSF/ANSI 49-2024 (Class II BSCs) and ANSI/ASHRAE 110-2016 (RA2025) for fume hood performance.

What a Chemical Fume Hood Does (and Doesn’t)

Fume hoods are exhaust devices that capture and remove chemical vapors, fumes, and particulates generated during procedures. Room air is drawn through the sash opening, across the work area, and exhausted to the outdoors via the building exhaust system. Performance is verified by ANSI/ASHRAE 110 containment testing.

Important note: Fume hoods do not provide product sterility or HEPA filtration and must not be used for biological product protection.

ANSI/ASHRAE 110-2016 (RA2025)

This standard defines how to test fume hood containment (factory and field). It is performance-based—it doesn’t prescribe airflow quantities but specifies how containment and airflow are measured across hood designs (e.g., bypass, VAV). Use it to commission new hoods and verify performance over time.

The purpose of this standard is to provide a quantitative and qualitative method for evaluating the fume containment of laboratory fume hoods. The test method considers the various factors that influence the performance of laboratory fume hoods, including the hood's aerodynamic design, the operation method, the stability of the exhaust ventilation system, the supply ventilation of the laboratory room, and the work practices of the user. The standard provides a reproducible method of testing laboratory hoods and gives a performance rating, including the influences of the laboratory arrangement and its ventilation system.

The desired hood performance should be defined through the cooperative efforts of the user, the chemical hygiene officer, the applications engineer, and other parties affected by the hood performance. The test method is a performance test and does not prescribe how much airflow should be present but specifies how the airflow should be measured.

What a Biosafety Cabinet Does (and Doesn’t)

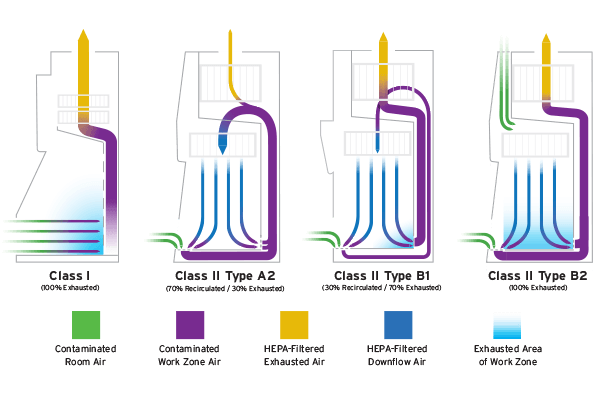

On the other hand, a biosafety cabinet is a type of enclosed laboratory equipment designed to protect from hazardous biological materials. Biosafety cabinets are used in laboratory settings where hazardous microorganisms, such as viruses and bacteria, are handled. The cabinets are designed to create a barrier between the laboratory worker and the hazardous material and to prevent the release of hazardous biological materials into the environment. Biosafety Cabinets are broken down into three different classes offering different levels of biological protection.

Class I Biosafety Cabinets

Class I BSCs provide personnel protection and environmental protection but no product protection. The Class I BSCs are typically used for hazardous non-sterile drug compoudning, animal cage dumping, culture aeration, tissue homogenization, or to enclose equipment such as centrifuges, harvesting equipment, or small fermenters, where aerosols may be generated but product protection is not required.

The Class I BSC operates by drawing unfiltered room air through the work opening and the work surface. The airflow is maintained at a minimum inward velocity of 75 linear feet per minute (lfm) through the front opening to ensure personnel protection. The air is then drawn into an exhaust plenum that contains a HEPA filter, which filters out any aerosols and particulates protecting the environment.

Class II Biosafety Cabinet Types

All Class II Type A1, A2, B1, B2, and C1 biosafety cabinets (BSCs) feature internal motor blowers that draw room air through the front grille to create inflow and personnel protection. This internal blower design distinguishes them from most chemical fume hoods, which, in most cases, depend entirely on an external exhaust system.

Type A1 and A2 Biosafety Cabinets

Type A1 and A2 BSCs recirculate approximately 70% of the cabinet air through high-efficiency particulate air (HEPA) filters to deliver clean, laminar downflow across the work surface, while about 30% is HEPA-filtered and exhausted. These cabinets protect personnel, product, and the environment by maintaining inward inflow and uniform downflow that minimizes cross-contamination.

Type A1 cabinets maintain a nominal inflow velocity of 75 fpm (0.38 m/s), while Type A2 cabinets operate at 100 fpm (0.51 m/s) as specified in NSF/ANSI 49-2022. Both may exhaust air back into the laboratory through HEPA filtration or vent externally through a canopy (thimble) connection. When a canopy is used, the system must include an alarm to detect exhaust loss and maintain airflow integrity.

Type B1 Biosafety Cabinet

Type B1 BSCs are hard-ducted to a dedicated building exhaust system and typically exhaust about 70% of total air volume while recirculating the remaining 30% through HEPA filters. Air drawn from the rear portion of the work surface is directly exhausted to remove potential volatile chemical vapors, while the front portion air is recirculated for product protection.

These cabinets are designed for work involving small amounts of volatile or toxic chemicals used concurrently with biological materials. They require an exhaust alarm and interlock that automatically shuts off the internal blower if exhaust airflow fails, per NSF/ANSI 49 testing requirements.

Type B2 Biosafety Cabinet

Type B2 BSCs provide total exhaust capability—100% of the air entering the cabinet is HEPA-filtered and discharged to the facility exhaust system, with no recirculation. The internal motor blower provides downflow air, but all air is exhausted, offering the highest level of chemical safety among Class II BSCs.

Because all air is exhausted, B2 cabinets depend on a reliable facility exhaust system and emergency power to maintain negative pressure and containment during operation interruptions.

Type C1 Biosafety Cabinet

The Type C1 BSC combines features of A2 and B1 cabinets, exhausting about 60% of air and recirculating 40% through HEPA filtration. While it offers flexible installation, it adds mechanical complexity with limited benefit.

Its depressed work zone and dedicated exhaust slots are prone to spills that can seep beneath the work surface, making cleanup more difficult and increasing contamination risk. When operated in recirculating mode, the C1 also releases filtered air back into the lab, affecting room balance and usable space.

In practice, the C1 functions much like a simplified B1—without the robustness of a true hard-ducted system. For most applications, a Type A2 or Type B1/B2 cabinet provides safer, cleaner, and more reliable long-term performance.

Operational Guidance

HEPA filters capture particulates and biological agents but do not remove vapors or gases. Therefore, only canopy-connected Type A1, A2, or C1 cabinets, or hard-ducted Type B1 and B2 cabinets, should be used for procedures involving volatile or toxic chemicals.

Hard-ducted B1 and B2 cabinets must be equipped with pressure-independent monitors and interlock alarm systems that automatically shut off the internal supply blower if the facility exhaust airflow is lost. This prevents air from being forced out the front opening, maintaining personnel and environmental protection during an exhaust failure.

Exhaust blowers can also be connected to emergency power to preserve negative pressure and containment during power interruptions, ensuring the cabinet remains in a safe, protective state until normal operation resumes.

Class III Biosafety Cabinets

The Class III BSC offers maximum protection against highly infectious microbiological agents and hazardous operations. A Class III BSC is a gas-tight enclosure with a non-opening view window and is equipped with a dunk tank or a double-door pass-through box for the passage of materials. This setup ensures the safety of the environment and the worker by preventing the release of hazardous materials into the surrounding area.

Supply and exhaust air is filtered by High-Efficiency Particulate Air (HEPA) filters, with exhaust air passing through two HEPA filters or a HEPA filter and an air incinerator before being discharged directly to the outdoors. The Class III BSC operates under negative pressure, which is maintained by an exhaust system exterior to the cabinet. This negative pressure ensures that if a breach occurs, the containment performance remains uncompromised, and the risk of exposure to hazardous materials is minimized.

Long, heavy-duty rubber gloves are attached to the cabinet in a gas-tight manner, allowing direct manipulation of materials isolated inside. This design ensures that the user's direct contact with hazardous materials is prevented while still allowing access. Although the gloves may restrict movement, the trade-off is on maximizing personal safety.

NSF/ANSI 49

NSF/ANSI 49: Design, Construction, Performance, and Field Certification of Biosafety Cabinetry is a comprehensive standard that dictates the specifics of design, construction, and performance of Class II (laminar flow) biosafety cabinets. The ultimate objective of this standard is to ensure that biosafety cabinets offer effective personnel, product, and environmental protection, demonstrate durability and reliability, and can be efficiently cleaned and decontaminated.

The standard elucidates numerous tests that the biosafety cabinets must successfully pass to meet the standard. Tests encompass basic necessities like durability, structural stability, cleanability, noise level, illumination, vibration, and motor/blower performance. Alongside these, the standard also emphasizes biological testing to ascertain the effectiveness of the cabinet in preventing contamination and ensuring user safety. This encompasses air containment and product protection tests, with rigorous procedures to verify that the cabinet maintains a sterile work environment and prevents exposure to potentially hazardous materials.

Cabinets that pass these collective tests are considered to have met the minimum requirements outlined in the standard. Variations in design and construction may still qualify under the standard, provided that appropriate tests and investigations indicate that the biosafety cabinet is durable, reliable, can be cleaned and decontaminated, and performs in accordance with the standard, including the imperative biological safety considerations.

Conclusion

Fume hoods and biosafety cabinets are designed to protect laboratory workers from hazardous materials. However, the type of protection provided by each is different. Fume hoods protect laboratory workers from inhaling toxic fumes and vapors from laboratory experiments or procedures. In contrast, biosafety cabinets are designed to protect laboratory workers from hazardous biological materials. Therefore, it is essential to choose the right type of equipment for a specific laboratory application to ensure the safety of the laboratory workers and the environment.