Article

Article

Illuminating Innovation: The Role of Yellow Lighting in Biosafety Cabinets

Why use yellow lighting in biosafety cabinets?

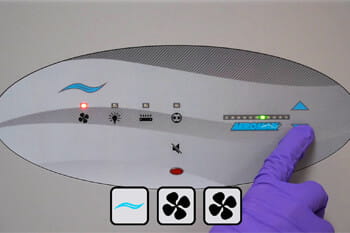

Yellow (amber) lighting in biosafety cabinets filters out blue and UV wavelengths to protect light-sensitive APIs, reagents, and culture media from photodegradation while work is performed under containment. This helps preserve sample potency, improve result accuracy, and support compliant pharmaceutical and research workflows.

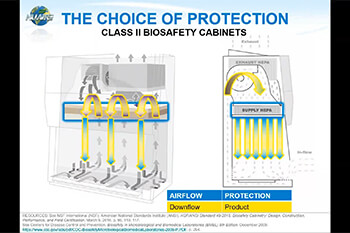

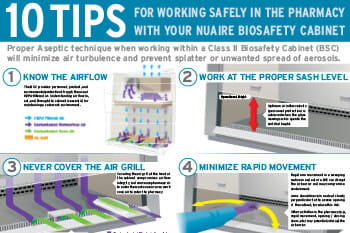

In modern pharmaceutical and biopharmaceutical laboratories, precision and contamination control define success. Every element of a biosafety cabinet (BSC)—from airflow dynamics to lighting configuration—protects both researchers and their work. One innovation attracting increasing attention is the use of yellow (amber) lighting inside biosafety cabinets.

What Is Yellow Light Used For in Laboratories?

Yellow (amber) light protects light-sensitive materials from photodegradation by filtering out high-energy blue and ultraviolet (UV) wavelengths, typically emitting above ~550 nm. This helps maintain the stability and potency of reagents, photo-reactive compounds, and culture media used in API compounding, sterility testing, and quality control.

- Prevents premature, light-induced reactions.

- Supports accurate, reproducible results and compliance.

- Extends usable life of high-value, light-sensitive materials.

Why Integrate Yellow Lighting into a Biosafety Cabinet?

Room-level lighting controls help, but integrating yellow lighting directly into the BSC delivers tighter protection and workflow control. Under NSF/ANSI 49–certified containment, technicians can handle photo-reactive substances without the risk of light-induced degradation while maintaining aseptic technique.

Ideal for:

- API compounding and formulation

- Media preparation and QC assays

- Photoreactive drug development and sterility testing

Customization and Collaboration: Built for Specialized Needs

Every lab is unique. NuAire engineers collaborate with your team to configure cabinets for precise applications—including amber-spectrum LEDs, visibility preferences, and ergonomic requirements—while preserving airflow performance and compliance. This partnership approach reflects our commitment to safety and lifetime support.

Practical Considerations for Yellow Lighting

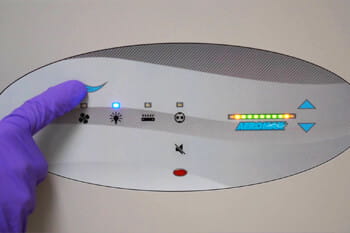

- Spectrum targeting: Aim for emission above ~550 nm to minimize blue/UV that triggers photochemistry.

- Light sources: Amber LEDs are energy-efficient and long-lasting; filters can adapt existing fixtures where needed.

- Human factors: Balance sample protection with operator visibility and task accuracy.

- Validation: Confirm target wavelengths and light levels during IQ/OQ/PQ alongside airflow and containment checks.

Lighting the Path Forward

The adoption of yellow lighting in biosafety cabinets shows how engineering precision and user collaboration can improve laboratory performance. Together with Kewaunee Scientific, NuAire delivers end-to-end laboratory environments—from design to discovery—helping global research teams protect people, science, and the future.

Plan Your Yellow-Lighting Configuration

Explore NuAire biosafety cabinets or connect with our team to integrate automation equipment and amber lighting for your workflow.