White Paper

White Paper

Primary Engineering Control Placement in the Cleanroom

Optimize PEC Placement for USP <797> & <800> Compliance

A strategic approach to Primary Engineering Control (PEC) placement can make the difference between seamless compliance and costly cleanroom redesigns. In Primary Engineering Control Placement in the Cleanroom, NuAire explores best practices for placing PECs that support sterile compounding and hazardous drug (HD) handling under USP <797> and USP <800>.

Why PEC Placement Matters in Cleanroom Design

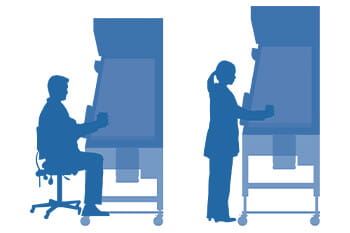

PECs are critical tools in maintaining ISO Class 5 air quality for compounded sterile preparations (CSPs). But simply installing a laminar airflow workbench (LAFW) or biological safety cabinet (BSC) isn’t enough—where and how you place it within the buffer zone or containment secondary engineering control (C-SEC) directly impacts airflow, contamination risk, and regulatory compliance.

From Class I BSCs and CVEs for nonsterile weighing to CACIs and Class II BSCs for sterile HDs, the paper details the placement considerations required for effective containment and protection.

Cleanroom Configurations that Support USP Requirements

Sterile Non-Hazardous PEC Strategies

For CSPs that do not involve hazardous ingredients, USP <797> emphasizes product protection. This guide illustrates compliant two-room, positive-pressure configurations using LAFWs or CAIs, emphasizing minimal airflow disruption and optimal technician ergonomics.

Sterile Hazardous Drug PEC Placement

When compounding HDs, USP <800> mandates negative pressure C-PECs with ISO Class 5 air, such as CACIs or Class II, Type B2 BSCs. This paper provides layout diagrams and explains minimum spacing (≥1 meter) when colocating nonsterile and sterile hoods.

How to Future-Proof Your Pharmacy's Cleanroom

Design for Growth and Workflow

This white paper encourages a proactive look at facility design trends, not just current needs. Learn how PEC placement ties into workflow optimization, personnel safety, and environmental controls in cleanrooms expected to meet increasing compounding volume and regulatory scrutiny.

Explore NuAire Cleanroom-Ready Compounding Solutions

If you're designing or retrofitting your cleanroom, NuAire provides expert insights and best-in-class equipment to meet your pharmacy's needs. Learn more about:

- Cleanroom Solutions for USP Compliance

- Biological Safety Cabinets for Sterile and Hazardous Compounding

- Compounding Aseptic and Containment Isolators (CAIs/CACIs)

- Creating a USP <800>-Compliant Cleanroom – Part 1

- Environmental Sampling Guidance – Part 3

Targeted for Sterile and HD Pharmacy Teams Across the U.S.

Whether you're in hospital pharmacy design in California, building a USP <800> compounding suite in Texas, or planning cleanroom renovations in Florida, this white paper is built for you. It aligns with U.S. regulatory bodies, including USP, NIOSH, FDA, and state boards of pharmacy.