PharmaGard NU-NR800 Compounding Aseptic Containment Isolator Restricted Access Barrier System

- Overview

- Specifications

- Reviews

- Resources

- Options

Overview

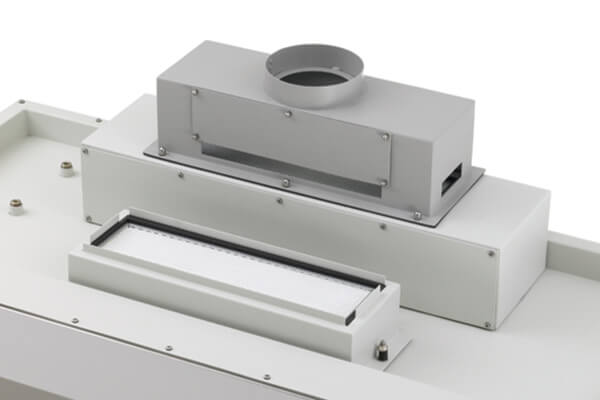

Exhaust Transition

Experience seamless integration and cost savings with the NuAire NU-916-797 exhaust transition, designed for pharmacies implementing the NU-NR800 unit. Comply effortlessly with USP 800 guidelines by connecting to an external exhaust blower while benefiting from the economic aspects of a canopy connection. The innovative recirculating design of the NU-NR800 demands significantly lower exhaust volumes than total exhaust systems, leading to substantial savings in installation and ongoing operational expenses.

Note: Accessory sold separately. A qualified risk assessment is recommended to ensure the recirculating model's appropriateness for compounding hazardous drugs.

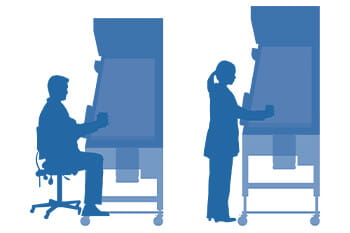

Safety and Useability

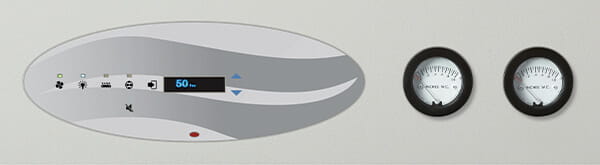

FlowGard Electronic Control System

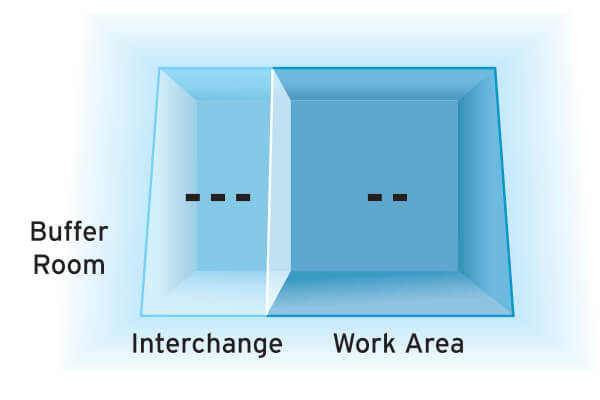

Maintaining Safety and Sterility

Sliding Work Tray

Three IV Bar Locations

Review

Resources

Manuals

Drawings

Specifications

BIM Revit

Request Your Quote for a NU-NR800

Thank you for completing the form.

We will be in touch. If you have any urgent questions, please reach out at 763-553-1270.