LabGard CYTO NU-581 Class II Type A2 Biosafety Cabinet

- Overview

- Specifications

- Reviews

- Resources

- Options

Overview

Triple HEPA Filtration for API Safety

TouchLink Control System

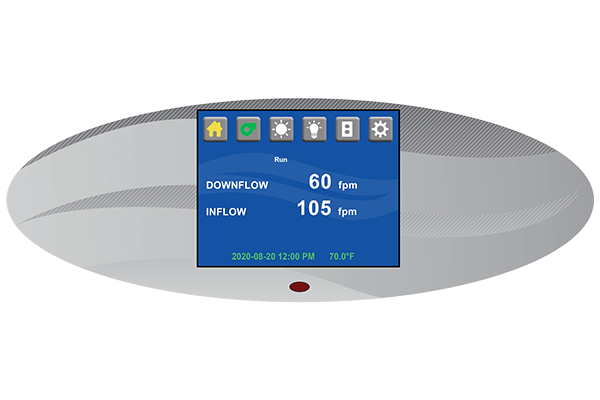

The TouchLink control system calculates inflow velocity based on the data received from the exhaust airflow sensor and displays it alongside the readings from the downflow sensor on the front panel. Touch screen control, historical monitoring, and configurable settings enable users to manage airflow when performance must be demonstrated and recorded.

Thermistor Exhaust Sensor

A single dual-thermistor airflow sensor in the exhaust measures airflow to enable the FlowGard to calculate inflow velocity for users desiring the most straightforward measurement of cabinet containment performance.

Downflow Air Sensor

The downflow sensor measures velocity inside the work zone and passes the data to the TouchLink display to assure users of product protection, a critical aspect in many pharmaceutical and biotechnology applications.

Specifications

| Blower Contact Wires | Optional |

| Cord Pass Through | Optional on Right and/or Left Side Wall |

| IV Bar with 6 Hooks | Optional |

| Motorized Base Stand | Optional |

| Motorized Window | Optional on 230V/50-60Hz Model |

| Outlet(s) | Standard, two backwall |

| Service Couplings (3/8-inch NPT) | Two Couplings on Left Side Wall and One on Right Side Wall are Standard, Maximum of Three Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | One Valve on Right Side Wall is Standard, Maximum of Three Each Side Wall Optional |

| Ultraviolet (UV) Light | Optional |

| Access Opening Glass Type | Safety Plate Glass |

| Armrest | Stainless Steel |

| Cabinet Construction | All welded stainless steel 16 GA, Type 304, 14 GA HRS Base |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 11 1/2-inch (292 mm) 99.99% Efficiency @ 0.3 Micron |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Motor(s) | 3/4 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | 99.995% Efficiency at MPPS |

| Style | Console |

| Supply Filter | 3-inch (76mm) 99.99% Efficiency on 0.3 microns |

| Viewing Window Inches (mm) | 18 (457) open to fully closed |

| Work Access Opening(s) | 8-inch (203mm) or 10-in (254mm) |

| Work Surface | One-Piece Dished Stainless Steel, Optional Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232, USB |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 43 (1092) |

| Est. Shipping Height Inches (mm) | 75 (1905) |

| Est. Shipping Width Inches (mm) | 58 (1473) |

| Exterior Depth Inches (mm) | 33 13/16 (859) |

| Exterior Depth with Armrest Removed Inches (mm) | 33 (838) |

| Exterior Height (Minimum for Transport) Inches (mm) | 79 3/8 (2016) |

| Exterior Height Inches (mm) | 86 7/8-92 7/8 (2207-2359) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 86 7/8 (2207) |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 92 7/8 (2359) |

| Exterior Width Inches (mm) | 54 7/8 (1394) |

| Nominal Width Feet (Meters) | 4 ft. (1.2m) |

| Useable Work Tray Area Depth Inches (mm) | 20 7/8 (530) |

| Useable Work Tray Area Width Inches (mm) | 45 7/8 (1165) |

| Work Area Depth Measured at 10-inches (254 mm) Window Height Inches (mm) | 26 (660) |

| Work Area Height Inches (mm) | 28 1/2 (724mm) |

| Work Area Width Inches (mm) | 46 3/8 (1178) |

| Blower/Lights Amps [10-inch (254 mm) Access Opening] | 6 |

| Blower/Lights Amps [12-inch (305 mm) Access Opening] | |

| Blower/Lights Amps [8-inch (203 mm) Access Opening] | 5.8 |

| Electrical Configuration | 115V 60Hz |

| Outlet Amps | 3 |

| Power Cord | 12 ft. 12 GA-3 Wire, 20A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 14 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | ≤ 58 dba |

| 10-inch (254 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | 434 (737) |

| 10-inch (254 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | 363-588 (617-1000) |

| 8-inch (203 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | 366 (622) |

| 8-inch (203 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | 295-520 (502-884) |

| Heat Rejected 10-inch (254 mm) Access Opening (BTU/Hour) | 2669 |

| Heat Rejected Vented (BTU/Hour) | 157 |

| Plant Duct Static Pressure Inches (mm) | 0.05-0.1"/1.27-2.54mm H2O |

| Performance Standard | EN-12469, DIN-12980 |

| Safety Certification | UL, UL-C |

| Air Cleanliness (ISO 14644) | ISO Class 5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | Dual Airflow Sensor |

| Control System | TouchLink |

| Est. Shipping Weight lbs (kg) | 750 (340) |

| Net Weight lbs (kg) | 700 (318) |

| Cord Pass Through | Optional on Right and/or Left Side Wall |

| Gas Supply Interlock with Blower | Optional |

| IV Bar with 6 Hooks | Optional |

| Motorized Base Stand | Optional |

| Motorized Window | Optional on 230V/50-60Hz Model |

| Outlet(s) | Standard, two backwall |

| Service Couplings (3/8-inch NPT) | Two Couplings on Left Side Wall and One on Right Side Wall are Standard, Maximum of Three Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | One Valve on Right Side Wall is Standard, Maximum of Three Each Side Wall Optional |

| Ultraviolet (UV) Light | Optional |

| Access Opening Glass Type | Safety Plate Glass |

| Armrest | Stainless Steel |

| Cabinet Construction | All welded stainless steel 16 GA, Type 304, 14 GA HRS Base |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 11 1/2-inch (292 mm) 99.995% Efficiency @ 0.3 micron |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Motor(s) | 3/4 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | 99.995% Efficiency @ MPPS |

| Style | Console |

| Supply Filter | 3-inch (76mm) 99.995% Efficiency @ 0.3 micron |

| Viewing Window Inches (mm) | 18 (457) open to fully closed |

| Work Access Opening(s) | 8-inch (203mm) |

| Work Surface | One-Piece Dished Stainless Steel, Optional Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232, USB |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 43 (1092) |

| Est. Shipping Height Inches (mm) | 75 (1905) |

| Est. Shipping Width Inches (mm) | 58 (1473) |

| Exterior Depth Inches (mm) | 33 13/16 (859) |

| Exterior Depth with Armrest Removed Inches (mm) | 33 (838) |

| Exterior Height (Minimum for Transport) Inches (mm) | 79 3/8 (2016) |

| Exterior Height Inches (mm) | 86 7/8-92 7/8 (2207-2359) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 86 7/8 (2207) |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 92 7/8 (2359) |

| Exterior Width Inches (mm) | 54 7/8 (1394) |

| Nominal Width Feet (Meters) | 4 ft. (1.2m) |

| Useable Work Tray Area Depth Inches (mm) | 20 7/8 (530) |

| Useable Work Tray Area Width Inches (mm) | 45 7/8 (1165) |

| Work Area Depth Measured at 8-inches (203 mm) Window Height Inches (mm) | 26 1/8 (664) |

| Work Area Height Inches (mm) | 28 1/2 (724mm) |

| Work Area Width Inches (mm) | 46 3/8 (1178) |

| Blower/Lights Amps [8-inch (203 mm) Access Opening] | 3.4 |

| Electrical Configuration | 230V 50/60Hz |

| Outlet Amps | 3 |

| Power Cord | 12 ft. 14 GA-3 Wire, 15A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 10 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | ≤ 58 dbA |

| 8-inch (203 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | 366 (622) |

| 8-inch (203 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | 295-520 (502-884) |

| Heat Rejected 8-inch (203 mm) Access Opening (BTU/Hour) | 2669 |

| Heat Rejected Vented (BTU/Hour) | 2669 |

| Plant Duct Static Pressure Inches (mm) | 0.05-0.1"/1.27-2.54mm H2O |

| Performance Standard | EN-12469, DIN-12980 |

| Safety Certification | UL, UL-C |

| Air Cleanliness (ISO 14644) | ISO Class 5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | Dual Airflow Sensor |

| Control System | TouchLink |

| Est. Shipping Weight lbs (kg) | 750 (340) |

| Net Weight lbs (kg) | 700 (318) |

| Blower Contact Wires | Optional |

| Cord Pass Through | Optional on Right and/or Left Side Wall |

| IV Bar with 6 Hooks | Optional |

| Motorized Base Stand | Optional |

| Motorized Window | Optional on 230V/50-60Hz Model |

| Outlet(s) | Standard, two backwall |

| Service Couplings (3/8-inch NPT) | Two Couplings on Left Side Wall and One on Right Side Wall are Standard, Maximum of Three Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | One Valve on Right Side Wall is Standard, Maximum of Three Each Side Wall Optional |

| Ultraviolet (UV) Light | Optional |

| Access Opening Glass Type | Safety Plate Glass |

| Armrest | Stainless Steel |

| Cabinet Construction | All welded stainless steel 16 GA, Type 304, 14 GA HRS Base |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 11 1/2-inch (292 mm) 99.99% Efficiency @ 0.3 Micron |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Motor(s) | 1 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | 99.995% Efficiency at MPPS |

| Style | Console |

| Supply Filter | 3-inch (76mm) 99.99% Efficiency on 0.3 microns |

| Viewing Window Inches (mm) | 18 (457) open to fully closed |

| Work Access Opening(s) | 8-inch (203mm) or 10-in (254mm) |

| Work Surface | One-Piece Dished Stainless Steel, Optional Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232, USB |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 43 (1092) |

| Est. Shipping Height Inches (mm) | 87 (2210) |

| Est. Shipping Width Inches (mm) | 77 (1956) |

| Exterior Depth Inches (mm) | 33 13/16 (859) |

| Exterior Depth with Armrest Removed Inches (mm) | 33 (838) |

| Exterior Height (Minimum for Transport) Inches (mm) | 79 3/8 (2016) |

| Exterior Height Inches (mm) | 86 7/8-92 7/8 (2207-2359) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 86 7/8 (2207) |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 92 7/8 (2359) |

| Exterior Width Inches (mm) | 66 7/8 (1699) |

| Nominal Width Feet (Meters) | 5 ft. (1.5m) |

| Useable Work Tray Area Depth Inches (mm) | 20 7/8 (530) |

| Useable Work Tray Area Width Inches (mm) | 57 7/8 (1470) |

| Work Area Depth Measured at 10-inches (254 mm) Window Height Inches (mm) | 26 (660) |

| Work Area Height Inches (mm) | 28 1/2 (724mm) |

| Work Area Width Inches (mm) | 58 3/8 (1483) |

| Blower/Lights Amps [10-inch (254 mm) Access Opening] | 6.4 |

| Blower/Lights Amps [12-inch (305 mm) Access Opening] | |

| Blower/Lights Amps [8-inch (203 mm) Access Opening] | 6.2 |

| Electrical Configuration | 115V 60Hz |

| Outlet Amps | 3 |

| Power Cord | 12 ft. 12 GA-3 Wire, 20A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 14 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | ≤ 59 dba |

| 10-inch (254 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | 544 (924) |

| 10-inch (254 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | 451-676 (766-1149) |

| 8-inch (203 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | 458 (778) |

| 8-inch (203 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | 365-590 (621-1003) |

| Heat Rejected 10-inch (254 mm) Access Opening (BTU/Hour) | 2983 |

| Heat Rejected Vented (BTU/Hour) | 198 |

| Plant Duct Static Pressure Inches (mm) | 0.05-0.1"/1.27-2.54mm H2O |

| Performance Standard | EN-12469, DIN-12980 |

| Safety Certification | UL, UL-C |

| Air Cleanliness (ISO 14644) | ISO Class 5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | Dual Airflow Sensor |

| Control System | TouchLink |

| Est. Shipping Weight lbs (kg) | 840 (381) |

| Net Weight lbs (kg) | 790 (358) |

| Cord Pass Through | Optional on Right and/or Left Side Wall |

| Gas Supply Interlock with Blower | Optional |

| IV Bar with 6 Hooks | Optional |

| Motorized Base Stand | Optional |

| Motorized Window | Optional on 230V/50-60Hz Model |

| Outlet(s) | Standard, two backwall |

| Service Couplings (3/8-inch NPT) | Two Couplings on Left Side Wall and One on Right Side Wall are Standard, Maximum of Three Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | One Valve on Right Side Wall is Standard, Maximum of Three Each Side Wall Optional |

| Ultraviolet (UV) Light | Optional |

| Access Opening Glass Type | Safety Plate Glass |

| Armrest | Stainless Steel |

| Cabinet Construction | All welded stainless steel 16 GA, Type 304, 14 GA HRS Base |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 11 1/2-inch (292 mm) 99.995% Efficiency @ 0.3 micron |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Motor(s) | 1 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | 99.995% Efficiency @ MPPS |

| Style | Console |

| Supply Filter | 3-inch (76mm) 99.995% Efficiency @ 0.3 micron |

| Viewing Window Inches (mm) | 18 (457) open to fully closed |

| Work Access Opening(s) | 8-inch (203mm) |

| Work Surface | One-Piece Dished Stainless Steel, Optional Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232, USB |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 43 (1092) |

| Est. Shipping Height Inches (mm) | 87 (2210) |

| Est. Shipping Width Inches (mm) | 77 (1956) |

| Exterior Depth Inches (mm) | 33 13/16 (859) |

| Exterior Depth with Armrest Removed Inches (mm) | 33 (838) |

| Exterior Height (Minimum for Transport) Inches (mm) | 79 3/8 (2016) |

| Exterior Height Inches (mm) | 86 7/8-92 7/8 (2207-2359) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 86 7/8 (2207) |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 92 7/8 (2359) |

| Exterior Width Inches (mm) | 66 7/8 (1699) |

| Nominal Width Feet (Meters) | 5 ft. (1.5m) |

| Useable Work Tray Area Depth Inches (mm) | 20 7/8 (530) |

| Useable Work Tray Area Width Inches (mm) | 57 7/8 (1470) |

| Work Area Depth Measured at 8-inches (203 mm) Window Height Inches (mm) | 26 1/8 (664) |

| Work Area Height Inches (mm) | 28 1/2 (724mm) |

| Work Area Width Inches (mm) | 58 3/8 (1483) |

| Blower/Lights Amps [8-inch (203 mm) Access Opening] | 3.8 |

| Electrical Configuration | 230V 50/60Hz |

| Outlet Amps | 3 |

| Power Cord | 12 ft. 14 GA-3 Wire, 15A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 11 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | ≤ 59 dbA |

| 8-inch (203 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | 458 (778) |

| 8-inch (203 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | 436-661 (741-1124) |

| Heat Rejected 8-inch (203 mm) Access Opening (BTU/Hour) | 2983 |

| Heat Rejected Vented (BTU/Hour) | 198 |

| Plant Duct Static Pressure Inches (mm) | 0.05-0.1"/1.27-2.54mm H2O |

| Performance Standard | EN-12469, DIN-12980 |

| Safety Certification | UL, UL-C |

| Air Cleanliness (ISO 14644) | ISO Class 5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | Dual Airflow Sensor |

| Control System | TouchLink |

| Est. Shipping Weight lbs (kg) | 840 (381) |

| Net Weight lbs (kg) | 790 (358) |

| Blower Contact Wires | Optional |

| Cord Pass Through | Optional on Right and/or Left Side Wall |

| IV Bar with 6 Hooks | Optional |

| Motorized Base Stand | Optional |

| Motorized Window | Optional on 230V/50-60Hz Model |

| Outlet(s) | Standard, two backwall |

| Service Couplings (3/8-inch NPT) | Two Couplings on Left Side Wall and One on Right Side Wall are Standard, Maximum of Three Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | One Valve on Right Side Wall is Standard, Maximum of Three Each Side Wall Optional |

| Ultraviolet (UV) Light | Optional |

| Access Opening Glass Type | Safety Plate Glass |

| Armrest | Stainless Steel |

| Cabinet Construction | All welded stainless steel 16 GA, Type 304, 14 GA HRS Base |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 11 1/2-inch (292 mm) 99.99% Efficiency @ 0.3 Micron |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Motor(s) | 1 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | 99.995% Efficiency at MPPS |

| Style | Console |

| Supply Filter | 3-inch (76mm) 99.99% Efficiency on 0.3 microns |

| Viewing Window Inches (mm) | 18 (457) open to fully closed |

| Work Access Opening(s) | 8-inch (203mm) or 10-in (254mm) |

| Work Surface | One-Piece Dished Stainless Steel, Optional Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232, USB |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 44 (1118) |

| Est. Shipping Height Inches (mm) | 87 (2210) |

| Est. Shipping Width Inches (mm) | 81 (2057) |

| Exterior Depth Inches (mm) | 33 13/16 (859) |

| Exterior Depth with Armrest Removed Inches (mm) | 33 (838) |

| Exterior Height (Minimum for Transport) Inches (mm) | 79 3/8 (2016) |

| Exterior Height Inches (mm) | 86 7/8-92 7/8 (2207-2359) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 86 7/8 (2207) |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 92 7/8 (2359) |

| Exterior Width Inches (mm) | 78 7/8 (2003) |

| Nominal Width Feet (Meters) | 6 ft. (1.8m) |

| Useable Work Tray Area Depth Inches (mm) | 20 7/8 (530) |

| Useable Work Tray Area Width Inches (mm) | 69 7/8 (1775) |

| Work Area Depth Measured at 10-inches (254 mm) Window Height Inches (mm) | 26 (660) |

| Work Area Height Inches (mm) | 28 1/2 (724mm) |

| Work Area Width Inches (mm) | 70 3/8 (1788) |

| Blower/Lights Amps [10-inch (254 mm) Access Opening] | 6.6 |

| Blower/Lights Amps [12-inch (305 mm) Access Opening] | |

| Blower/Lights Amps [8-inch (203 mm) Access Opening] | 6.4 |

| Electrical Configuration | 115V 60Hz |

| Outlet Amps | 3 |

| Power Cord | 12 ft. 12 GA-3 Wire, 20A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 14 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | ≤ 60 dba |

| 10-inch (254 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | 649 (1103) |

| 10-inch (254 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | 538-763 (915-1297) |

| 8-inch (203 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | 547 (929) |

| 8-inch (203 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | 436-661 (741-1124) |

| Heat Rejected 10-inch (254 mm) Access Opening (BTU/Hour) | 3140 |

| Heat Rejected Vented (BTU/Hour) | 198 |

| Plant Duct Static Pressure Inches (mm) | 0.05-0.1"/1.27-2.54mm H2O |

| Performance Standard | EN-12469, DIN-12980 |

| Safety Certification | UL, UL-C |

| Air Cleanliness (ISO 14644) | ISO Class 5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | Dual Airflow Sensor |

| Control System | TouchLink |

| Est. Shipping Weight lbs (kg) | 930 (422) |

| Net Weight lbs (kg) | 880 (399) |

| Cord Pass Through | Optional on Right and/or Left Side Wall |

| Gas Supply Interlock with Blower | Optional |

| IV Bar with 6 Hooks | Optional |

| Motorized Base Stand | Optional |

| Motorized Window | Optional on 230V/50-60Hz Model |

| Outlet(s) | Standard, two backwall |

| Service Couplings (3/8-inch NPT) | Two Couplings on Left Side Wall and One on Right Side Wall are Standard, Maximum of Three Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | One Valve on Right Side Wall is Standard, Maximum of Three Each Side Wall Optional |

| Ultraviolet (UV) Light | Optional |

| Access Opening Glass Type | Safety Plate Glass |

| Armrest | Stainless Steel |

| Cabinet Construction | All welded stainless steel 16 GA, Type 304, 14 GA HRS Base |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 11 1/2-inch (292 mm) 99.995% Efficiency @ 0.3 micron |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Motor(s) | 1 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | 99.995% Efficiency @ MPPS |

| Style | Console |

| Supply Filter | 3-inch (76mm) 99.995% Efficiency @ 0.3 micron |

| Viewing Window Inches (mm) | 18 (457) open to fully closed |

| Work Access Opening(s) | 8-inch (203mm) |

| Work Surface | One-Piece Dished Stainless Steel, Optional Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232, USB |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 44 (1118) |

| Est. Shipping Height Inches (mm) | 87 (2210) |

| Est. Shipping Width Inches (mm) | 81 (2057) |

| Exterior Depth Inches (mm) | 33 13/16 (859) |

| Exterior Depth with Armrest Removed Inches (mm) | 33 (838) |

| Exterior Height (Minimum for Transport) Inches (mm) | 79 3/8 (2016) |

| Exterior Height Inches (mm) | 86 7/8-92 7/8 (2207-2359) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 86 7/8 (2207) |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 92 7/8 (2359) |

| Exterior Width Inches (mm) | 78 7/8 (2003) |

| Nominal Width Feet (Meters) | 6 ft. (1.8m) |

| Useable Work Tray Area Depth Inches (mm) | 20 7/8 (530) |

| Useable Work Tray Area Width Inches (mm) | 69 7/8 (1775) |

| Work Area Depth Measured at 8-inches (203 mm) Window Height Inches (mm) | 26 1/8 (664) |

| Work Area Height Inches (mm) | 28 1/2 (724mm) |

| Work Area Width Inches (mm) | 70 3/8 (1788) |

| Blower/Lights Amps [8-inch (203 mm) Access Opening] | 4 |

| Electrical Configuration | 230V 50/60Hz |

| Outlet Amps | 3 |

| Power Cord | 12 ft. 14 GA-3 Wire, 15A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 11 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | ≤ 60 dbA |

| 8-inch (203 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | 547 (929) |

| 8-inch (203 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | 436-661 (741-1124) |

| Heat Rejected 8-inch (203 mm) Access Opening (BTU/Hour) | 3140 |

| Heat Rejected Vented (BTU/Hour) | 198 |

| Plant Duct Static Pressure Inches (mm) | 0.05-0.1"/1.27-2.54mm H2O |

| Performance Standard | EN-12469, DIN-12980 |

| Safety Certification | UL, UL-C |

| Air Cleanliness (ISO 14644) | ISO Class 5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | Dual Airflow Sensor |

| Control System | TouchLink |

| Est. Shipping Weight lbs (kg) | 930 (422) |

| Net Weight lbs (kg) | 880 (399) |

Review

Resources

Brochures

Drawings

-

NU-581-600E, 1.8 Meter Biosafety Cabinet Drawing (230V)

-

NU-581-600, 6-foot Biosafety Cabinet Drawing (115V)

-

NU-581-500E, 1.5 Meter Biosafety Cabinet Drawing (230V)

-

NU-581-500, 5-foot Biosafety Cabinet Drawing (115V)

-

NU-581-400E, 1.2 Meter Biosafety Cabinet Drawing (230V)

-

NU-581-400, 4-foot Biosafety Cabinet Drawing (115V)

Specifications

Request Your Quote for a NU-581

Thank you for completing the form.

We will be in touch. If you have any urgent questions, please reach out at 763-553-1270.