Article

Article

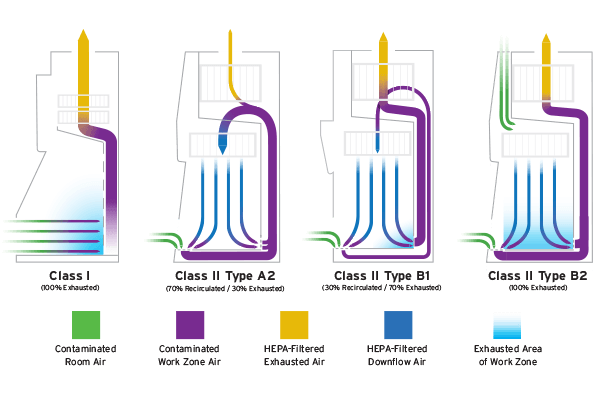

Biosafety Cabinet Types

Biosafety cabinets are essential safety devices in laboratories, designed to safeguard personnel, research materials, and the environment from airborne contaminants. This guide explains the different BSC classes and types, how each uses airflow to create containment, and how to choose the right cabinet for your applications.

Understanding Biosafety Cabinets

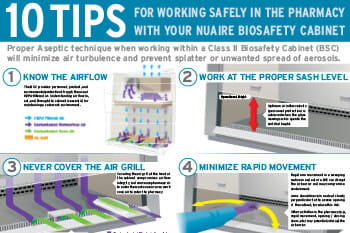

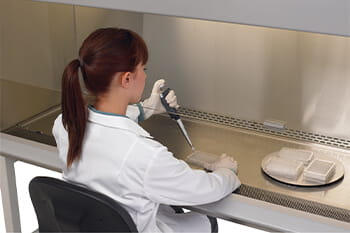

A biosafety cabinet is a ventilated containment enclosure that uses controlled inflow, downflow, and HEPA filtration to prevent contaminants from escaping the work area. BSCs provide protection by managing airflow patterns to shield operators, maintain product sterility, and limit environmental exposure.

Biosafety Cabinet Classes and Types

Class I BSC

Protection: Personnel and environment

Product protection: None

Class I BSCs draw air into the cabinet and exhaust it through a HEPA filter, protecting the user and environment from particulates. They are suited for general microbiology where product sterility is not required.

Class II BSCs

Class II BSCs provide personnel, product, and environmental protection. They are the most commonly used BSCs in clinical, pharmaceutical, academic, and biotechnology laboratories.

- Type A1 BSCs

Used for standard microbiological work without volatile chemicals. A1 cabinets maintain ≥75 fpm inflow and recirculate approximately 70% of air while exhausting 30% through HEPA filtration. Not suitable for hazardous chemical use.

- Type A2 BSCs

Similar to Type A1 but with ≥100 fpm inflow for enhanced containment. A2 cabinets can handle minute amounts of volatile chemicals when connected to a thimble (canopy) exhaust. Common in clinical labs, biotechnology, and pharmaceutical compounding. Learn more about Type A2 BSCs.

- Type B1 BSCs

Designed for microbiology workflows involving small quantities of toxic chemicals or radionuclides when used toward the rear of the work surface. Approximately 70% of air is exhausted and 30% recirculated through HEPA filters. Learn more about Type B1 BSCs.

- Type B2 BSCs (Total Exhaust)

These cabinets exhaust 100% of air through dedicated ductwork with no recirculation, making them suitable for higher levels of toxic chemical use and radionuclide applications. Minimum inflow of 100 fpm. Learn more about Type B2 BSCs.

- Type C1 BSCs

A flexible, hybrid design that operates in A-mode or B-mode depending on chemical usage. Type C1 cabinets provide adaptability for laboratories with mixed biological and chemical workflows. Learn more about Type C1 BSCs.

Class III BSCs

Protection: Maximum (BSL-3/4 applications)

Construction: Gas-tight, negative-pressure glovebox

Class III cabinets provide the highest level of containment. Operators work through sealed glove ports, and all air is HEPA-filtered and exhausted outside the facility. These cabinets are used for high-risk pathogens or hazardous particulates. Learn more about Class III BSCs.

Selecting the Right Biosafety Cabinet

Choosing the correct BSC requires evaluating:

- Biological risk level (BSL-1 through BSL-4)

- Need for personnel, product, or environmental protection

- Presence of volatile chemicals or radionuclides

- HVAC and exhaust capabilities

- Workflow requirements (cell culture, compounding, diagnostics, etc.)

NuAire biosafety cabinets are engineered to meet NSF/ANSI 49, USP <797>/<800>, and global biosafety standards.

Conclusion

Understanding the differences between BSC classes and types ensures proper selection, safe operation, and regulatory compliance. Whether handling routine microbiological procedures or high-risk materials, choosing the correct biosafety cabinet—and maintaining regular certification—helps protect your team, your research, and your laboratory environment.