Article

Article

How an Animal Refuse Workstation (Cage Dump Station) Works

In a busy vivarium, the simple act of dumping bedding can create a surprising amount of airborne dust, dander, and allergen-containing particles. Over time, repeated exposure during routine cage dumping can affect technician comfort and respiratory health.

An animal refuse workstation—often called a cage dump station—is designed to address this specific task by controlling airflow at the point where waste becomes airborne. This article explains how these workstations function, why they are used, and what veterinary medicine directors and animal care staff should understand about their role in daily operations.

What Is an Animal Refuse Workstation?

An animal refuse workstation is a Class I personnel-protection enclosure used for disposing of animal bedding and cage waste. Its primary purpose is to help reduce a worker’s exposure to airborne particulates generated during dumping activities.

Because it is a Class I enclosure, the workstation is designed to protect people, not to maintain a sterile work environment. It is intended for “dirty” tasks such as bedding disposal rather than animal handling or clean cage preparation.

Why Cage Dumping Creates Exposure Risk

Bedding materials such as corn cob, wood fiber, or paper-based products can release fine dust when cages are emptied. Shaking or tapping cages to remove compacted bedding can further increase airborne particles.

Even when personal protective equipment is worn, repeated exposure over months or years can contribute to irritation or sensitization. For this reason, many vivariums rely on engineering controls—like refuse workstations—to reduce exposure at the source.

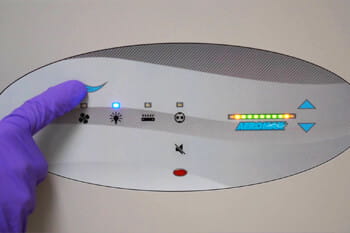

The Airflow Principle: Creating an Inward Air Barrier

The defining feature of an animal refuse workstation is the inward airflow at the front access opening. Room air is drawn into the opening, forming an invisible “air barrier” between the operator and the waste.

When bedding is dumped inside the enclosure, airborne particles are pulled away from the user’s breathing zone and into the cabinet rather than drifting outward into the room.

Why Placement and Room Air Matter

The air barrier is only effective if it is not overwhelmed by room drafts. Strong air currents from doors, supply diffusers, or heavy foot traffic can disrupt containment. Proper placement within the room is therefore essential to consistent performance.

How Air Moves Through the Workstation

In a typical configuration, air follows a single-pass path. Room air enters through the front opening, passes across the work zone, and then moves through internal filtration before being exhausted.

This controlled airflow path helps ensure that particles released during cage dumping are captured and filtered rather than allowed to escape back into the room.

Filtration: Capturing Dust, Dander, and Fine Particles

Prefiltration

A prefilter is commonly used to capture larger particles and extend the life of the primary HEPA filter. This layer handles much of the visible dust generated during dumping.

HEPA Filtration

High-efficiency particulate air (HEPA) filters are designed to capture very small particles that remain airborne. These filters are effective at removing fine dust and allergen-sized particulates associated with animal bedding and waste.

Odor Control

Some workstations include activated carbon filtration to help reduce odors from soiled bedding. Odor control improves comfort but does not replace particle filtration or good technique.

Typical Workflow for Technicians

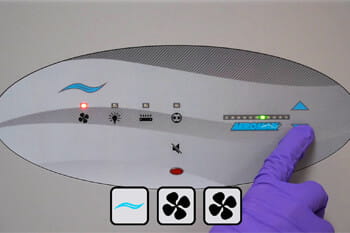

1. Start-Up

The blower is allowed to run briefly before work begins so airflow can stabilize and the air barrier is fully established.

2. Cage Dumping

Cages are emptied completely inside the enclosure. Bedding is dumped into a lined container or bag positioned within the work zone to keep airborne particles inside the capture area.

3. Movement and Technique

Smooth, deliberate movements help maintain containment. Fast or sweeping motions can disrupt airflow and increase the chance of particles escaping.

4. Post-Task Purge

After dumping is complete, allowing the workstation to continue running briefly helps clear residual airborne particles before shutdown or cleaning.

What an Animal Refuse Workstation Does Not Do

It is important to understand the limitations of this equipment. An animal refuse workstation does not:

- Create a sterile or clean work surface

- Replace biosafety cabinets for infectious or hazardous procedures

- Eliminate the need for appropriate PPE and good technique

Why These Workstations Matter

For veterinary medicine directors and facility leaders, animal refuse workstations support safer, more consistent waste-handling practices across teams and shifts. For technicians, they help reduce dust, odor, and discomfort during one of the most repetitive tasks in the vivarium.

When properly placed, used correctly, and maintained through routine verification, these workstations serve as a practical engineering control that quietly supports long-term staff health.

Key Takeaways for Vet Med Directors and Animal Care Teams

- Primary purpose: reduce personnel exposure to airborne allergens during bedding disposal and cage dumping.

- How it works: inward airflow at the front opening pulls particles into the enclosure instead of into the room.

- Why technique matters: smooth motions and minimizing drafts help maintain the air barrier.

- Filtration role: prefilters capture larger dust; HEPA filtration captures fine particulates before exhaust/recirculation.

- Not for sterility: Class I enclosures protect people—not product sterility or a “clean” workspace.

References and Guidance

For policy, engineering control selection, and occupational health programs in animal facilities, these sources are commonly referenced:

Frequently Asked Questions About How Animal Refuse Workstations Work

Why is cage dumping considered a high-exposure task?

Cage dumping can release fine bedding dust, animal dander, and waste particles into the air. Shaking or tapping cages increases aerosolization, making this task a common source of allergen exposure in vivariums.

How does inward airflow protect technicians during bedding disposal?

Inward airflow creates an air barrier at the front opening that pulls airborne particles away from the technician’s breathing zone and into the enclosure, reducing the chance of contaminants escaping into the room.

Why doesn’t an animal refuse workstation create a sterile work area?

Animal refuse workstations are designed as Class I enclosures, meaning room air flows into the cabinet to protect personnel. Because air is not HEPA-filtered before entering the work zone, sterility is not maintained.

What role does HEPA filtration play in allergen control?

HEPA filtration captures fine airborne particulates generated during bedding disposal after they are pulled into the enclosure. This helps reduce allergen recirculation into the room environment.

How can room conditions affect containment performance?

Strong drafts from doors, supply diffusers, or high traffic areas can disrupt the inward airflow barrier. Proper placement and minimizing cross-drafts help maintain effective containment during use.

Does technician technique affect how well the workstation works?

Yes. Smooth, deliberate movements and keeping dumping actions fully inside the work zone help maintain airflow capture. Rapid or sweeping motions can disrupt containment and increase particle escape.

When is an animal refuse workstation most effective?

These workstations are most effective during routine, repetitive cage dumping tasks where airborne particulates are generated, especially in high-throughput vivariums with frequent bedding disposal.