LabGard LP NU-640 Class II Type A2 Biosafety Cabinet

- Overview

- Specifications

- Reviews

- Resources

- Options

Overview

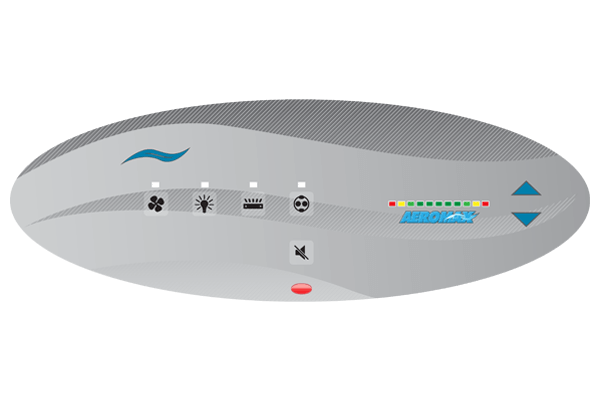

AeroMax Control System

The AeroMax control system visualizes airflow plenum pressure through a series of multicolored lights and activates both an audible and visual alarm whenever cabinet performance departs from normal parameters.

Ergonomic Efficiency

The NU-640, with its innovative console model design, stands out as the quintessential solution for vivariums challenged by low ceiling heights. Its low-profile structure is specifically crafted to fit into spaces where traditional cabinets wouldn't, offering unmatched adaptability. However, it's not just about fitting in; the NU-640 prioritizes operator comfort and safety. Its unique design includes an adjustable work surface height feature, ensuring that technicians of any stature can find their perfect working position. This focus on ergonomics is crucial in reducing workplace injuries associated with repetitive tasks, a common concern in laboratory environments. With the NU-640, vivariums no longer have to compromise on space, functionality, or staff well-being.

Industry Leading Work Access Opening

The NU-640 revolutionizes vivarium operations with its unprecedentedly large access opening, specifically designed to accommodate the effortless entry and removal of even the largest rat cages. This expansive opening removes the everyday struggle of maneuvering bulky items in and out of a confined space, making the process seamless. The cabinet's enhanced 14-inch (356mm) work access opening height is a game-changer, significantly expanding the usable work zone. This innovative feature provides lab animal technicians with the invaluable flexibility to move their arms and hands freely above the cages, substantially simplifying cage transfers. With the NU-640, routine tasks are no longer cumbersome, thanks to the thoughtfully designed access dimensions that transform operational efficiency and ease.

Pre-filter Extends Life and Lowers Cost

The durability of primary supply and exhaust HEPA filters is paramount. Here, the unique challenge is the presence of animal hair and dander, which can swiftly overwhelm and reduce the efficacy of standard filters. However, this concern is effectively addressed with a specialized, reusable pre-filter positioned strategically beneath the work surface. This pre-filter is engineered to capture larger particulates, safeguarding the primary HEPA filters and allowing them to function more efficiently against finer contaminants. Not only does this extend the life of the HEPA filters, but the reusability of the pre-filter also curtails the need for frequent and potentially expensive replacements. Additionally, the cabinet's innovative design features a prop-up work surface, granting easy access for prompt and hassle-free cleaning and maintenance of the pre-filter. This thoughtful integration of features underscores a commitment to operational longevity and cost-effectiveness.

Specifications

| Blower Contact Wires | N/A |

| Closure Panels | N/A |

| Cord Pass Through | N/A |

| Double Exhaust HEPA Filter | N/A |

| Gas Supply Interlock with Blower | N/A |

| Glass Sidewalls | N/A |

| IV Bar with 6 Hooks | N/A |

| Magnifying Glass in Window | N/A |

| Motorized Base Stand | Included |

| Motorized Window | N/A |

| Other Built-in Supply Filter Option(s) | N/A |

| Outlet(s) | Standard, two backwall |

| Plumbing | N/A |

| Remote Service Valves | N/A |

| Seismic Brackets or Studs | N/A |

| Service Couplings (3/8-inch NPT) | None, Maximum of Two Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | None, Maximum of Two Each Side Wall Optional |

| Side Panels | N/A |

| Smooth Interior | N/A |

| Ultraviolet (UV) Light | N/A |

| Window Edge Protector | Optional |

| Access Opening Glass Type | Safety Glass |

| Armrest | Optional, Stainless Steel |

| Cabinet Construction | All welded stainless steel 16/18 gauge, Type 304 pressure tight design |

| Casters | 5" (13mm) Casters Standard |

| Decontamination Seal-able Window | N/A |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 6-inch (152 mm) 99.99% Efficiency @ 0.3 Micron |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | N/A-Multi-Piece Steel Construction |

| Motor(s) | 3/4 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | Underneath Work Surface |

| Style | Console |

| Supply Filter | 3-inch (76mm) 99.99% Efficiency @ 0.3 Micron |

| Viewing Window Inches (mm) | 23.875 (607) Safety Glass/Hinged |

| Work Access Opening(s) | 14-inches (356 mm) |

| Work Surface | One-Piece Flat Stainless Steel with Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232 |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 39 (991) |

| Est. Shipping Height Inches (mm) | 87 (2210) |

| Est. Shipping Width Inches (mm) | 55 (1397) |

| Exterior Depth Inches (mm) | 32 7/8 (835) |

| Exterior Depth with Armrest Removed Inches (mm) | 33 (838) |

| Exterior Height (Minimum for Transport) Inches (mm) | 78.25 (1987) |

| Exterior Height Inches (mm) | 78 1/4-86 1/4 (1987-2190) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 78 1/4 (1987) with 35-in (890mm) Work Surface Height |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 86 1/4 (2190) with 43-in (1093) Work Surface Height |

| Exterior Width Inches (mm) | 56.375 (1433) Including push/pull bars |

| Nominal Width Feet (Meters) | 4 (1.2) |

| Useable Work Tray Area Depth Inches (mm) | 19 (482) |

| Useable Work Tray Area Width Inches (mm) | 46.2 (1173) |

| Work Area Depth Measured at 10-inches (254 mm) Window Height Inches (mm) | N/A |

| Work Area Depth Measured at 12-inches (305 mm) Window Height Inches (mm) | N/A |

| Work Area Depth Measured at 14-inches (356 mm) Window Height Inches (mm) | 22.75 (579) |

| Work Area Depth Measured at 8-inches (203 mm) Window Height Inches (mm) | N/A |

| Work Area Height Inches (mm) | 24.625 (626) |

| Work Area Width Inches (mm) | 46.5 (1181) |

| Blower/Lights Amps [10-inch (254 mm) Access Opening] | |

| Blower/Lights Amps [12-inch (305 mm) Access Opening] | |

| Blower/Lights Amps [14-inch (356mm) Access Opening] | 4.8 |

| Blower/Lights Amps [8-inch (203 mm) Access Opening] | |

| Electrical Configuration | 115V60Hz |

| Junction Box | N/A |

| Outlet Amps | 3 |

| Power Cord | 12 gauge - 3 Wire, 20A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 14 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | Inquire |

| 10-inch (254 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | N/A |

| 10-inch (254 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | N/A |

| 12-inch (305 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | N/A |

| 12-inch (305 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | N/A |

| 14-inch (356mm) Opening Exhaust Requirement for Fixed Canopy (NU-926) CFM(CMH) | 609 (1035) |

| 14-inch (356mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM(CMH) | 575-725 (977-1232) |

| 8-inch (203 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | N/A |

| 8-inch (203 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | N/A |

| Bag In Bag Out | N/A |

| Heat Rejected 10-inch (254 mm) Access Opening (BTU/Hour) | N/A |

| Heat Rejected 12-inch (305 mm) Access Opening (BTU/Hour) | N/A |

| Heat Rejected 14-inch (356 mm) Access Opening (BTU/Hour) | 1883 |

| Heat Rejected 8-inch (203 mm) Access Opening (BTU/Hour) | N/A |

| Heat Rejected Vented (BTU/Hour) | 198 |

| Other Built-in Exhaust Option(s) | N/A |

| Plant Duct Static Pressure Inches (mm) | 0.05-0.1"/1.27-2.54mm H2O |

| Australian Test Method | N/A |

| Performance Standard | |

| Safety Certification |

| Air Cleanliness (ISO 14644) | ISO-Class-5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | Pressure |

| Control System | AeroMax |

| Est. Shipping Weight lbs (kg) | 610 lbs. / 277 kg. |

| Net Weight lbs (kg) | 560 lbs. / 254 kg. |

| Blower Contact Wires | N/A |

| Closure Panels | N/A |

| Cord Pass Through | N/A |

| Double Exhaust HEPA Filter | N/A |

| Gas Supply Interlock with Blower | N/A |

| Glass Sidewalls | N/A |

| IV Bar with 6 Hooks | N/A |

| Magnifying Glass in Window | N/A |

| Motorized Base Stand | Included |

| Motorized Window | N/A |

| Other Built-in Supply Filter Option(s) | N/A |

| Outlet(s) | Standard, two backwall |

| Plumbing | N/A |

| Remote Service Valves | N/A |

| Seismic Brackets or Studs | N/A |

| Service Couplings (3/8-inch NPT) | None, Maximum of Two Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | None, Maximum of Two Each Side Wall Optional |

| Side Panels | N/A |

| Smooth Interior | N/A |

| Ultraviolet (UV) Light | N/A |

| Window Edge Protector | Optional |

| Access Opening Glass Type | Safety Glass |

| Armrest | Optional, Stainless Steel |

| Cabinet Construction | All welded stainless steel 16/18 gauge, Type 304 pressure tight design |

| Casters | 5" (13mm) Casters Standard |

| Decontamination Seal-able Window | N/A |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 6-inch (152 mm) 99.99% Efficiency @ 0.3 Micron |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | N/A-Multi-Piece Steel Construction |

| Motor(s) | 1 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | Underneath Work Surface |

| Style | Console |

| Supply Filter | 3-inch (76mm) 99.99% Efficiency @ 0.3 Micron |

| Viewing Window Inches (mm) | 23.875 (607) Safety Glass/Hinged |

| Work Access Opening(s) | 14-inch (356 mm) |

| Work Surface | One-Piece Flat Stainless Steel with Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232 |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 39 (991) |

| Est. Shipping Height Inches (mm) | 87 (2210) |

| Est. Shipping Width Inches (mm) | 73 (1854) |

| Exterior Depth Inches (mm) | 32 7/8 (835) |

| Exterior Depth with Armrest Removed Inches (mm) | 33 (838) |

| Exterior Height (Minimum for Transport) Inches (mm) | 78 1/4 (1987) |

| Exterior Height Inches (mm) | 78 1/4-86 1/4 (1987-2190) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 78 1/4 (1987) with 35-in (890mm) Work Surface Height |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 86 1/4 (2190) with 43-in (1093) Work Surface Height |

| Exterior Width Inches (mm) | 68 3/8 (1737) including push/pull bars |

| Nominal Width Feet (Meters) | 5 ft. (1.5m) |

| Useable Work Tray Area Depth Inches (mm) | 19 (482) |

| Useable Work Tray Area Width Inches (mm) | 58.2 (1478) |

| Work Area Depth Measured at 10-inches (254 mm) Window Height Inches (mm) | N/A |

| Work Area Depth Measured at 12-inches (305 mm) Window Height Inches (mm) | N/A |

| Work Area Depth Measured at 14-inches (356 mm) Window Height Inches (mm) | 22 3/4 (579) |

| Work Area Depth Measured at 8-inches (203 mm) Window Height Inches (mm) | N/A |

| Work Area Height Inches (mm) | 24 5/8 (626) |

| Work Area Width Inches (mm) | 58 1/2 (1486) |

| Blower/Lights Amps [10-inch (254 mm) Access Opening] | |

| Blower/Lights Amps [12-inch (305 mm) Access Opening] | |

| Blower/Lights Amps [14-inch (356mm) Access Opening] | 5.6 |

| Blower/Lights Amps [8-inch (203 mm) Access Opening] | |

| Electrical Configuration | 115V60Hz |

| Junction Box | N/A |

| Outlet Amps | 3 |

| Power Cord | 12 ft. 12 GA-3 Wire, 20A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 16 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | Inquire |

| 10-inch (254 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | N/A |

| 10-inch (254 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | N/A |

| 12-inch (305 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | N/A |

| 12-inch (305 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | N/A |

| 14-inch (356mm) Opening Exhaust Requirement for Fixed Canopy (NU-926) CFM(CMH) | 731 (1242) |

| 14-inch (356mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM(CMH) | 699-829 (1188-1408) |

| 8-inch (203 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | N/A |

| 8-inch (203 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | N/A |

| Bag In Bag Out | N/A |

| Heat Rejected 10-inch (254 mm) Access Opening (BTU/Hour) | N/A |

| Heat Rejected 12-inch (305 mm) Access Opening (BTU/Hour) | N/A |

| Heat Rejected 14-inch (356 mm) Access Opening (BTU/Hour) | 2197 |

| Heat Rejected 8-inch (203 mm) Access Opening (BTU/Hour) | N/A |

| Heat Rejected Vented (BTU/Hour) | 198 |

| Other Built-in Exhaust Option(s) | N/A |

| Plant Duct Static Pressure Inches (mm) | 0.05-0.1"/1.27-2.54mm H2O |

| Australian Test Method | N/A |

| Performance Standard | |

| Safety Certification |

| Air Cleanliness (ISO 14644) | ISO-Class-5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | Pressure |

| Control System | AeroMax |

| Est. Shipping Weight lbs (kg) | 700 (318) |

| Net Weight lbs (kg) | 650 (295) |

| Blower Contact Wires | N/A |

| Closure Panels | N/A |

| Cord Pass Through | N/A |

| Double Exhaust HEPA Filter | N/A |

| Gas Supply Interlock with Blower | N/A |

| Glass Sidewalls | N/A |

| IV Bar with 6 Hooks | N/A |

| Magnifying Glass in Window | N/A |

| Motorized Base Stand | Included |

| Motorized Window | N/A |

| Other Built-in Supply Filter Option(s) | N/A |

| Outlet(s) | Standard, two backwall |

| Plumbing | N/A |

| Remote Service Valves | N/A |

| Seismic Brackets or Studs | N/A |

| Service Couplings (3/8-inch NPT) | None, Maximum of Two Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | None, Maximum of Two Each Side Wall Optional |

| Side Panels | N/A |

| Smooth Interior | N/A |

| Ultraviolet (UV) Light | N/A |

| Window Edge Protector | Optional |

| Access Opening Glass Type | Safety Glass |

| Armrest | Optional, Stainless Steel |

| Cabinet Construction | All welded stainless steel 16/18 gauge, Type 304 pressure tight design |

| Casters | 5" (13mm) Casters Standard |

| Decontamination Seal-able Window | N/A |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 6-inch (152 mm) 99.99% Efficiency @ 0.3 Micron |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | N/A-Multi-Piece Steel Construction |

| Motor(s) | 1 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | Underneath Work Surface |

| Style | Console |

| Supply Filter | 3-inch (76mm) 99.99% Efficiency @ 0.3 Micron |

| Viewing Window Inches (mm) | 23.875 (607) Safety Glass/Hinged |

| Work Access Opening(s) | 14-inch (356) |

| Work Surface | One-Piece Flat Stainless Steel with Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232 |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 39 (991) |

| Est. Shipping Height Inches (mm) | 87 (2210) |

| Est. Shipping Width Inches (mm) | 81 (2057) |

| Exterior Depth Inches (mm) | 32 7/8 (835) |

| Exterior Depth with Armrest Removed Inches (mm) | 33 (838) |

| Exterior Height (Minimum for Transport) Inches (mm) | 78 1/4 (1987) |

| Exterior Height Inches (mm) | 78 1/4-86 1/4 (1987-2190) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 78 1/4 (1987) with 35-in (890mm) Work Surface Height |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 86 1/4 (2190) with 43-in (1093) Work Surface Height |

| Exterior Width Inches (mm) | 80 3/8 (2042) |

| Nominal Width Feet (Meters) | 6 ft. (1.8m) |

| Useable Work Tray Area Depth Inches (mm) | 19 (482) |

| Useable Work Tray Area Width Inches (mm) | 70 (1783) |

| Work Area Depth Measured at 10-inches (254 mm) Window Height Inches (mm) | N/A |

| Work Area Depth Measured at 12-inches (305 mm) Window Height Inches (mm) | N/A |

| Work Area Depth Measured at 14-inches (356 mm) Window Height Inches (mm) | 22 3/4 (579) |

| Work Area Depth Measured at 8-inches (203 mm) Window Height Inches (mm) | N/A |

| Work Area Height Inches (mm) | 24 5/8 (626) |

| Work Area Width Inches (mm) | 70 1/2 (1791) |

| Blower/Lights Amps [10-inch (254 mm) Access Opening] | |

| Blower/Lights Amps [12-inch (305 mm) Access Opening] | |

| Blower/Lights Amps [14-inch (356mm) Access Opening] | 6.0 |

| Blower/Lights Amps [8-inch (203 mm) Access Opening] | |

| Electrical Configuration | 115V60Hz |

| Junction Box | N/A |

| Outlet Amps | 3 |

| Power Cord | 12 ft. 12 GA-3 Wire, 20A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 16 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | Inquire |

| 10-inch (254 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | N/A |

| 10-inch (254 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | N/A |

| 12-inch (305 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | N/A |

| 12-inch (305 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | N/A |

| 14-inch (356mm) Opening Exhaust Requirement for Fixed Canopy (NU-926) CFM(CMH) | 888 (1509) |

| 14-inch (356mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM(CMH) | 880-970 (1495-1648) |

| 8-inch (203 mm) Opening Exhaust Requirement for Fixed Canopy (NU-907/NU-916) CFM (CMH) | N/A |

| 8-inch (203 mm) Opening Exhaust Requirement for Variable Flow Canopy (NU-911) CFM (CMH) | N/A |

| Bag In Bag Out | N/A |

| Heat Rejected 10-inch (254 mm) Access Opening (BTU/Hour) | N/A |

| Heat Rejected 12-inch (305 mm) Access Opening (BTU/Hour) | N/A |

| Heat Rejected 14-inch (356 mm) Access Opening (BTU/Hour) | 2354 |

| Heat Rejected 8-inch (203 mm) Access Opening (BTU/Hour) | N/A |

| Heat Rejected Vented (BTU/Hour) | 2354 |

| Other Built-in Exhaust Option(s) | N/A |

| Plant Duct Static Pressure Inches (mm) | 0.05-0.1"/1.27-2.54mm H2O |

| Australian Test Method | N/A |

| Performance Standard | |

| Safety Certification |

| Air Cleanliness (ISO 14644) | ISO-Class-5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | Pressure |

| Control System | AeroMax |

| Est. Shipping Weight lbs (kg) | 790 (358) |

| Net Weight lbs (kg) | 740 (336) |

Review

Resources

Brochures

Drawings

BIM Revit

Request Your Quote for a NU-640

Thank you for completing the form.

We will be in touch. If you have any urgent questions, please reach out at 763-553-1270.