White Paper

White Paper

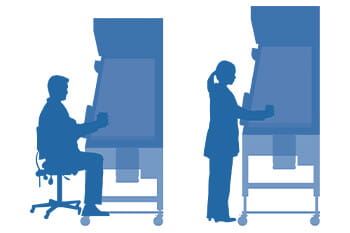

Improve Workflow with Cleanroom Design

Designing a cleanroom requires a multifaceted process that should reflect the facility's compounding model-comprising drug volumes, types (hazardous or nonhazardous, etc-while also considering the pharmacists and technicians, equipment, workflow, and processes. In addition, guidance from regulatory entities, such as state boards of pharmacy, accreditation organizations, the United States Pharmacopeia (USP), and the Federal Drug Administration (FDA) should be studied closely. This paper will focus on 503A pharmacy requirements and the USP chapters <797> and <800>. It is essential to recognize all of the above stakeholders during the cleanroom design process to improve workflow and optimize compliance.