Article

Article

Understanding the NSF/ANSI 49 Standard: Ensuring Safety and Efficiency in Biosafety Cabinets

Understanding the NSF/ANSI 49 Standard: Ensuring Safety and Efficiency in Biosafety Cabinets

In the realm of scientific research, particularly within the fields of biotechnology, microbiology, and pharmaceutical development, maintaining a controlled and safe environment is paramount. This is where the NSF/ANSI 49 standard comes into play, serving as a critical benchmark for biosafety cabinets' design, construction, and performance (BSCs). Let's delve into what NSF/ANSI 49 entails and why it is a cornerstone of laboratory safety and efficiency.

What is NSF/ANSI 49?

The NSF/ANSI 49 standard, developed by the National Sanitation Foundation (NSF) in collaboration with the American National Standards Institute (ANSI), outlines the minimum requirements for biosafety cabinets' design, construction, and performance. BSCs are specialized containment units used in laboratories to protect personnel, the environment, and products from potentially harmful aerosols and pathogens that may be present during research and experimentation.

Critical Components of the NSF/ANSI 49 Standard

The NSF/ANSI 49 standard addresses several critical aspects of BSC design and functionality, including:

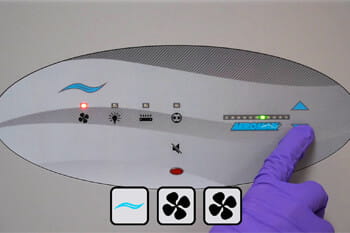

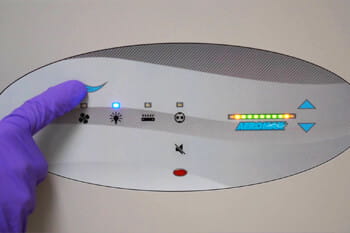

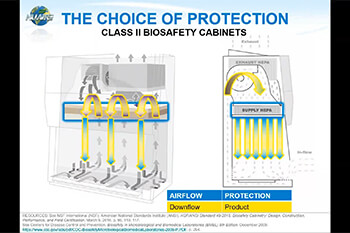

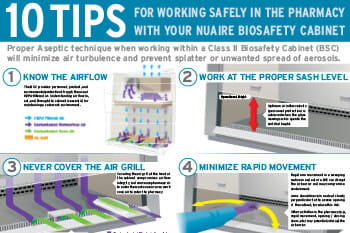

- Airflow Velocity and Patterns: It specifies the required airflow velocities and patterns within the cabinet to ensure containment and protection.

- HEPA Filtration: The standard mandates using High-Efficiency Particulate Air (HEPA) filters to capture 99.99% of particulates 0.3 microns in size, ensuring that the air exiting the cabinet is clean and free from contaminants.

- Construction Materials: It defines the materials and construction methods that ensure durability, ease of cleaning, and corrosion resistance.

- Noise and Vibration: The standard limits noise and vibration levels to create a comfortable working environment for laboratory personnel.

- Illumination: Adequate lighting conditions within the BSC are outlined to ensure users can perform tasks with visibility and precision.

- Performance Testing: NSF/ANSI 49 includes rigorous performance testing criteria to verify that BSCs meet the specified personnel, product, and environmental protection requirements.

Why is NSF/ANSI 49 Important?

The significance of the NSF/ANSI 49 standard in laboratory safety and efficiency cannot be overstated:

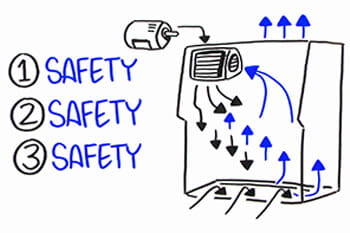

- Protects Personnel: By ensuring that BSCs effectively contain and filter hazardous particulates, the standard protects laboratory personnel from exposure to infectious agents and harmful substances.

- Prevents Cross-Contamination: Combined with aseptic technique, the specified airflow patterns and HEPA filtration reduce the risk of cross-contamination, safeguarding the integrity of research samples and experiments.

- Ensures Environmental Safety: The standard guarantees that the air exhausted from the cabinet is free from contaminants, thereby protecting the external environment.

- Facilitates Compliance: Laboratories that use NSF/ANSI 49 certified BSCs can demonstrate compliance with regulatory requirements, enhancing their credibility and operational standards.

- Promotes Uniformity: The standard provides a uniform benchmark for manufacturers and users, ensuring that all BSCs meet a consistent level of safety and performance.

Conclusion

The NSF/ANSI 49 standard is indispensable for laboratory safety and research integrity. Establishing rigorous requirements for biosafety cabinets not only protects laboratory personnel and the environment but also supports the scientific community in conducting safe and productive research. As such, understanding and adhering to the NSF/ANSI 49 standard is essential for laboratories aiming to maintain the highest safety, efficiency, and compliance levels.