LabGard ES TE NU-560 Class II Type B2 Biosafety Cabinet

- Overview

- Specifications

- Reviews

- Resources

- Options

Overview

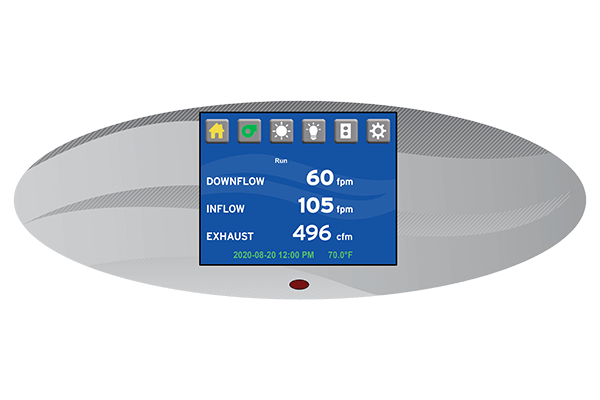

TouchLink Control System

The airflow dynamics in an externally exhausted type B2 cabinet need to work in constant harmony. The TouchLink control system displays inflow velocity, downflow velocity, and exhaust volume on a single, easy to read front screen. The digital control system interlocks the downflow blower with the external exhaust to shut down the motor if an exhaust failure occurs—a safeguard that is further backed up by a mechanical pressure switch.

Digital Exhaust Flow Grid

The digital differential velocity pressure flow monitors exhaust to enable the TouchLink to derive not only inflow velocity but also the critical parameter of exhaust volume for display to the cabinet operator.

Downflow Air Sensor

The downflow sensor measures velocity inside the work zone and passes the data to the TouchLink display to assure users of product protection, a critical aspect in many pharmaceutical and biotechnology applications.

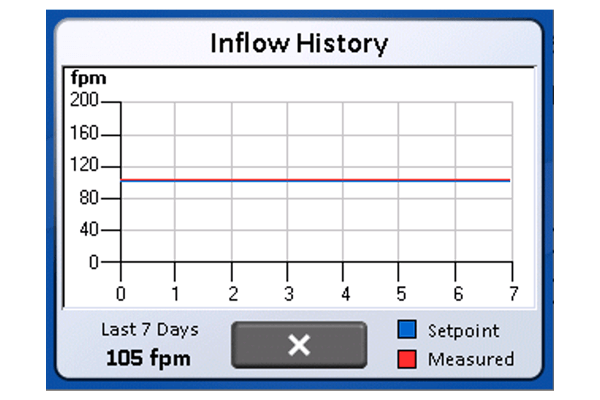

Performance History

The TouchLink control panel showcases a week's worth of cabinet performance data on-screen, while also facilitating the download of a full month's operational history to a USB. This feature is essential for procedures requiring documented airflow conditions in compliance with Good Manufacturing Practice (GMP) standards.

Specifications

| Airflow Control Options | Air Supply On/Off (Requires NU-952-012), Cabinet Off Override, Delay Off Exhaust Airflow, Exhaust Airflow Loss Override |

| Blower Contact Wires | N/A |

| Closure Panels | Optional Rear Closure Panels for Seismic Brackets |

| Cord Pass Through | Standard Right |

| Gas Supply Interlock with Blower | N/A |

| Glass Sidewalls | N/A |

| IV Bar with 6 Hooks | Optional |

| Motorized Base Stand | Optional as Separate Accessory |

| Motorized Window | N/A |

| Other Built-in Supply Filter Option(s) | N/A |

| Outlet(s) | One Left Front Faring, Optional One Right Front Faring |

| Plumbing | Optional 3/8" Soft Copper, 3/8" Black Pipe (Gas Only), or 1/2" Rigid Copper |

| Remote Service Valves | Maximum of Three Each Side Wall Optional |

| Seismic Brackets or Studs | Optional Rear or Floor Mount Seismic Brackets |

| Service Couplings (3/8-inch NPT) | Two Couplings on Left Side Wall and One on Right Side Wall are Standard, Maximum of Three Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | One Valve on Right Side Wall is Standard, Maximum of Three Each Side Wall Optional |

| Side Panels | Optional with Plumbing out Bottom, Top or Back |

| Smooth Interior | Optional (UV will not be available) |

| Ultraviolet (UV) Light | Optional |

| Window Edge Protector | Optional |

| Access Opening Glass Type | Tempered Glass |

| Cabinet Construction | All welded stainless steel 16/18 GA, Type 304 pressure tight design |

| Casters | N/A |

| Decontamination Seal-able Window | N/A |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 11 1/2-inch (292 mm) 99.99% Efficiency on 0.3 Microns |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Motor(s) | 1/2 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | N/A |

| Style | Bench top, optional base stand |

| Supply Filter | 3-inch (76mm) 99.99% Efficiency on 0.3 microns |

| Viewing Window Inches (mm) | 18.5 (470) open to fully closed |

| Work Access Opening(s) | 8-inch (203mm) |

| Work Surface | One-Piece Dished Stainless Steel with Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232, USB |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 43 (1092) |

| Est. Shipping Height Inches (mm) | 72 (1829) |

| Est. Shipping Width Inches (mm) | 58 (1473) |

| Exterior Depth with Armrest Removed Inches (mm) | 32 3/8 (823) |

| Exterior Height (Minimum for Transport) Inches (mm) | 62 (1575) |

| Exterior Height Inches (mm) | 62 (1575) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 88 1/2 (2248) |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 94 1/2 (2401) |

| Exterior Width Inches (mm) | 53 5/8 (1362) |

| Nominal Width Feet (Meters) | 4 ft. (1.2m) |

| Useable Work Tray Area Depth Inches (mm) | 20 7/8 (530) |

| Useable Work Tray Area Width Inches (mm) | 45 7/8 (1165) |

| Work Area Depth Measured at 8-inches (203 mm) Window Height Inches (mm) | 26 (660) |

| Work Area Height Inches (mm) | 25 3/16 (640) |

| Work Area Width Inches (mm) | 46 3/8 (1178) |

| Blower/Lights Amps | 2.1 |

| Electrical Configuration | 115V60Hz |

| Junction Box | Optional |

| Outlet Amps | 3 |

| Power Cord | 14 GA - 3 Wire, 15A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 8 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | Inquire |

| Bag In Bag Out | Optional |

| Direct Connection Exhaust Requirement Concurrent Balance Value, CFM(CMH) | 815 (1385) |

| Other Built-in Exhaust Option(s) | N/A |

| Plant Duct Static Pressure Inches (mm) | 1.7 w.g. (43mm w.g.) |

| Performance Standard | NSF-ANSI-49 |

| Safety Certification | UL, UL-C |

| Air Cleanliness (ISO 14644) | ISO-Class-5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Heat Rejected (BTU/Hour) | 474 |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | AirflowSensorPressureGrid |

| Control System | TouchLink |

| Est. Shipping Weight lbs (kg) | 540 (245) |

| Net Weight lbs (kg) | 490 (222) |

| Airflow Control Options | Air Supply On/Off (Requires NU-952-012), Cabinet Off Override, Delay Off Exhaust Airflow, Exhaust Airflow Loss Override |

| Blower Contact Wires | N/A |

| Closure Panels | Optional Rear Closure Panels for Seismic Brackets |

| Cord Pass Through | Standard Right |

| Gas Supply Interlock with Blower | N/A |

| Glass Sidewalls | N/A |

| IV Bar with 6 Hooks | Optional |

| Motorized Base Stand | Optional as Separate Accessory |

| Motorized Window | N/A |

| Other Built-in Supply Filter Option(s) | N/A |

| Outlet(s) | One Left Front Faring, Optional One Right Front Faring |

| Plumbing | Optional 3/8" Soft Copper, 3/8" Black Pipe (Gas Only), or 1/2" Rigid Copper |

| Remote Service Valves | Maximum of Three Each Side Wall Optional |

| Seismic Brackets or Studs | Optional Rear or Floor Mount Seismic Brackets |

| Service Couplings (3/8-inch NPT) | Two Couplings on Left Side Wall and One on Right Side Wall are Standard, Maximum of Three Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | One Valve on Right Side Wall is Standard, Maximum of Three Each Side Wall Optional |

| Side Panels | Optional with Plumbing out Bottom, Top or Back |

| Smooth Interior | N/A |

| Ultraviolet (UV) Light | Optional |

| Window Edge Protector | Optional |

| Access Opening Glass Type | Tempered Glass |

| Cabinet Construction | All welded stainless steel 16/18 GA, Type 304 pressure tight design |

| Casters | N/A |

| Decontamination Seal-able Window | N/A |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 11 1/2-inch (292 mm) 99.99% Efficiency on 0.3 Microns |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Motor(s) | 1/2 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | N/A |

| Style | Bench top, optional base stand |

| Supply Filter | 3-inch (76mm) 99.99% Efficiency on 0.3 microns |

| Viewing Window Inches (mm) | 18.5 (470) open to fully closed |

| Work Access Opening(s) | 8-inch (203mm) |

| Work Surface | One-Piece Dished Stainless Steel with Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232, USB |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 43 (1092) |

| Est. Shipping Height Inches (mm) | 72 (1829) |

| Est. Shipping Width Inches (mm) | 58 (1473) |

| Exterior Depth with Armrest Removed Inches (mm) | 32 3/8 (823) |

| Exterior Height (Minimum for Transport) Inches (mm) | 62 (1575) |

| Exterior Height Inches (mm) | 62 (1575) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 88 1/2 (2248) |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 94 1/2 (2401) |

| Exterior Width Inches (mm) | 53 5/8 (1362) |

| Nominal Width Feet (Meters) | 4 ft. (1.2m) |

| Useable Work Tray Area Depth Inches (mm) | 20 7/8 (530) |

| Useable Work Tray Area Width Inches (mm) | 45 7/8 (1165) |

| Work Area Depth Measured at 8-inches (203 mm) Window Height Inches (mm) | 26 (660) |

| Work Area Height Inches (mm) | 25 3/16 (640) |

| Work Area Width Inches (mm) | 46 3/8 (1178) |

| Blower/Lights Amps | 1 |

| Electrical Configuration | 230V5060Hz |

| Junction Box | Optional |

| Outlet Amps | 3 |

| Power Cord | 14 GA - 3 Wire, 16A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 7 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | Inquire |

| Bag In Bag Out | Optional |

| Direct Connection Exhaust Requirement Concurrent Balance Value, CFM(CMH) | 815 (1385) |

| Other Built-in Exhaust Option(s) | N/A |

| Plant Duct Static Pressure Inches (mm) | 1.7 w.g. (43mm w.g.) |

| Performance Standard | NSF-ANSI-49 |

| Safety Certification |

| Air Cleanliness (ISO 14644) | ISO-Class-5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Heat Rejected (BTU/Hour) | 474 |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | AirflowSensorPressureGrid |

| Control System | TouchLink |

| Est. Shipping Weight lbs (kg) | 540 (245) |

| Net Weight lbs (kg) | 490 (222) |

| Airflow Control Options | Air Supply On/Off (Requires NU-952-012), Cabinet Off Override, Delay Off Exhaust Airflow, Exhaust Airflow Loss Override |

| Blower Contact Wires | N/A |

| Closure Panels | Optional Rear Closure Panels for Seismic Brackets |

| Cord Pass Through | Standard Right |

| Gas Supply Interlock with Blower | N/A |

| Glass Sidewalls | N/A |

| IV Bar with 6 Hooks | Optional |

| Motorized Base Stand | Optional as Separate Accessory |

| Motorized Window | N/A |

| Other Built-in Supply Filter Option(s) | N/A |

| Outlet(s) | One Left Front Faring, Optional One Right Front Faring |

| Plumbing | Optional 3/8" Soft Copper, 3/8" Black Pipe (Gas Only), or 1/2" Rigid Copper |

| Remote Service Valves | Maximum of Three Each Side Wall Optional |

| Seismic Brackets or Studs | Optional Rear or Floor Mount Seismic Brackets |

| Service Couplings (3/8-inch NPT) | Two Couplings on Left Side Wall and One on Right Side Wall are Standard, Maximum of Three Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | One Valve on Right Side Wall is Standard, Maximum of Three Each Side Wall Optional |

| Side Panels | Optional with Plumbing out Bottom, Top or Back |

| Smooth Interior | Optional (UV will not be available) |

| Ultraviolet (UV) Light | Optional |

| Window Edge Protector | Optional |

| Access Opening Glass Type | Tempered Glass |

| Cabinet Construction | All welded stainless steel 16/18 GA, Type 304 pressure tight design |

| Casters | N/A |

| Decontamination Seal-able Window | N/A |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 11 1/2-inch (292 mm) 99.99% Efficiency on 0.3 Microns |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Motor(s) | 1/2 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | N/A |

| Style | Bench top, optional base stand |

| Supply Filter | 3-inch (76mm) 99.99% Efficiency on 0.3 microns |

| Viewing Window Inches (mm) | 18.5 (470) open to fully closed |

| Work Access Opening(s) | 8-inch (203mm) |

| Work Surface | One-Piece Dished Stainless Steel with Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232, USB |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 43 (1092) |

| Est. Shipping Height Inches (mm) | 73 (1854) |

| Est. Shipping Width Inches (mm) | 82 (2083) |

| Exterior Depth with Armrest Removed Inches (mm) | 32 3/8 (823) |

| Exterior Height (Minimum for Transport) Inches (mm) | 62 (1575) |

| Exterior Height Inches (mm) | 62 (1575) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 88 1/2 (2248) |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 94 1/2 (2401) |

| Exterior Width Inches (mm) | 77 5/8 (1972) |

| Nominal Width Feet (Meters) | 6 ft. (1.2m) |

| Useable Work Tray Area Depth Inches (mm) | 20 7/8 (530) |

| Useable Work Tray Area Width Inches (mm) | 69 7/8 (1775) |

| Work Area Depth Measured at 8-inches (203 mm) Window Height Inches (mm) | 26 (660) |

| Work Area Height Inches (mm) | 25 3/16 (640) |

| Work Area Width Inches (mm) | 70 3/8 (1788) |

| Blower/Lights Amps | 2.6 |

| Electrical Configuration | 115V60Hz |

| Junction Box | Optional |

| Outlet Amps | 3 |

| Power Cord | 14 GA - 3 Wire, 15A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 10 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | Inquire |

| Bag In Bag Out | Optional |

| Direct Connection Exhaust Requirement Concurrent Balance Value, CFM(CMH) | 1275 (2166) |

| Other Built-in Exhaust Option(s) | N/A |

| Plant Duct Static Pressure Inches (mm) | 1.8 w.g. (46mm w.g.) |

| Performance Standard | NSF-ANSI-49 |

| Safety Certification | UL, UL-C |

| Air Cleanliness (ISO 14644) | ISO-Class-5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Heat Rejected (BTU/Hour) | 584 |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | AirflowSensorPressureGrid |

| Control System | TouchLink |

| Est. Shipping Weight lbs (kg) | 730 (331) |

| Net Weight lbs (kg) | 680 (308) |

| Airflow Control Options | Air Supply On/Off (Requires NU-952-012), Cabinet Off Override, Delay Off Exhaust Airflow, Exhaust Airflow Loss Override |

| Blower Contact Wires | N/A |

| Closure Panels | Optional Rear Closure Panels for Seismic Brackets |

| Cord Pass Through | Standard Right |

| Gas Supply Interlock with Blower | N/A |

| Glass Sidewalls | N/A |

| IV Bar with 6 Hooks | Optional |

| Motorized Base Stand | Optional as Separate Accessory |

| Motorized Window | N/A |

| Other Built-in Supply Filter Option(s) | N/A |

| Outlet(s) | One Left Front Faring, Optional One Right Front Faring |

| Plumbing | Optional 3/8" Soft Copper, 3/8" Black Pipe (Gas Only), or 1/2" Rigid Copper |

| Remote Service Valves | Maximum of Three Each Side Wall Optional |

| Seismic Brackets or Studs | Optional Rear or Floor Mount Seismic Brackets |

| Service Couplings (3/8-inch NPT) | Two Couplings on Left Side Wall and One on Right Side Wall are Standard, Maximum of Three Each Side Wall Optional |

| Service Valves (3/8-inch NPT) | One Valve on Right Side Wall is Standard, Maximum of Three Each Side Wall Optional |

| Side Panels | Optional with Plumbing out Bottom, Top or Back |

| Smooth Interior | N/A |

| Ultraviolet (UV) Light | Optional |

| Window Edge Protector | Optional |

| Access Opening Glass Type | Tempered Glass |

| Cabinet Construction | All welded stainless steel 16/18 GA, Type 304 pressure tight design |

| Casters | N/A |

| Decontamination Seal-able Window | N/A |

| Diffuser | Metal, non-flammable |

| Drain Valve Location | Front right |

| Exhaust Filter | 11 1/2-inch (292 mm) 99.99% Efficiency on 0.3 Microns |

| Front & Control Panel Material | Painted Steel |

| HEPA Filter Seal Type | HEPEX Zero Leak Neoprene Seal, Spring-loaded |

| Lighting | LED |

| Main Cabinet Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Motor(s) | 1/2 HP DC ECM |

| Plenum Type | HEPEX |

| Pre-filter | N/A |

| Style | Bench top, optional base stand |

| Supply Filter | 3-inch (76mm) 99.99% Efficiency on 0.3 microns |

| Viewing Window Inches (mm) | 18.5 (470) open to fully closed |

| Work Access Opening(s) | 8-inch (203mm) |

| Work Surface | One-Piece Dished Stainless Steel with Prop-Up Rod |

| Work Zone Wrap | Single Piece Stainless Steel Side and Back Wall Construction |

| Data Output Features | RS-232, USB |

| Remote Alarm Terminals | Standard |

| Est. Shipping Depth Inches (mm) | 43 (1092) |

| Est. Shipping Height Inches (mm) | 73 (1854) |

| Est. Shipping Width Inches (mm) | 82 (2083) |

| Exterior Depth with Armrest Removed Inches (mm) | 32 3/8 (823) |

| Exterior Height (Minimum for Transport) Inches (mm) | 62 (1575) |

| Exterior Height Inches (mm) | 62 (1575) |

| Exterior Height with 30-inch (762 mm) Work Surface Height inches (mm) | 88 1/2 (2248) |

| Exterior Height with 36-inch (915 mm) Work Surface Height inches (mm) | 94 1/2 (2401) |

| Exterior Width Inches (mm) | 77 5/8 (1972) |

| Nominal Width Feet (Meters) | 6 ft. (1.2m) |

| Useable Work Tray Area Depth Inches (mm) | 20 7/8 (530) |

| Useable Work Tray Area Width Inches (mm) | 69 7/8 (1775) |

| Work Area Depth Measured at 8-inches (203 mm) Window Height Inches (mm) | 26 (660) |

| Work Area Height Inches (mm) | 25 3/16 (640) |

| Work Area Width Inches (mm) | 70 3/8 (1788) |

| Blower/Lights Amps | 1.3 |

| Electrical Configuration | 230V5060Hz |

| Junction Box | Optional |

| Outlet Amps | 3 |

| Power Cord | 14 GA - 3 Wire, 16A |

| Power Cord Length Foot (Meter) | 12 (3.7) |

| Rated Amps | 7 |

| Light Intensity fc (Lux) | 90-120 (968-1291) |

| Reach into workzone Inches (mm) | 6 (152) |

| Sound Pressure Level per ISO 4871 | Inquire |

| Bag In Bag Out | Optional |

| Direct Connection Exhaust Requirement Concurrent Balance Value, CFM(CMH) | 1275 (2166) |

| Other Built-in Exhaust Option(s) | N/A |

| Plant Duct Static Pressure Inches (mm) | 1.8 w.g. (46mm w.g.) |

| Performance Standard | NSF-ANSI-49 |

| Safety Certification |

| Air Cleanliness (ISO 14644) | ISO-Class-5 |

| Downflow fpm (m/s) | 60 fpm (0.30 m/s) |

| Fumigation: per NIH/NSF Procedures | True |

| Heat Rejected (BTU/Hour) | 584 |

| Inflow fpm (m/s) | 105 fpm (0.53 m/s) |

| Protection | Product, Personnel, Environmental |

| Airflow Monitor | AirflowSensorPressureGrid |

| Control System | TouchLink |

| Est. Shipping Weight lbs (kg) | 730 (331) |

| Net Weight lbs (kg) | 680 (308) |

Review

Resources

Manuals

Videos

Specifications

Request Your Quote for a NU-560

Thank you for completing the form.

We will be in touch. If you have any urgent questions, please reach out at 763-553-1270.