Video

Video

Understanding the Biosafety Cabinet

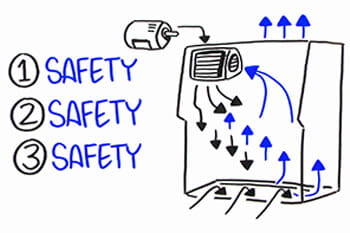

The video "Understanding the Biosafety Cabinet" offers a comprehensive overview of how Biological Safety Cabinets (BSCs) have evolved to become essential tools in protecting laboratory workers from infections, hazardous biological materials, and aerosols. From historical outbreaks to modern challenges posed by antibiotic-resistant bacteria and mutating viruses, BSCs mitigate risks in laboratory settings by providing a controlled, safe environment for handling potentially dangerous substances.

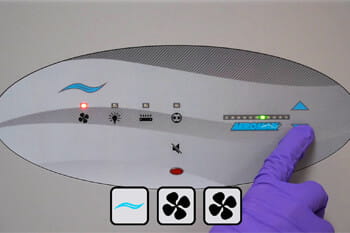

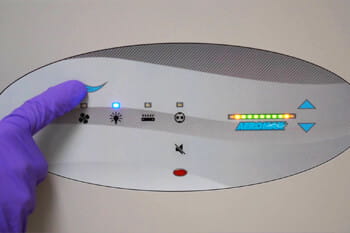

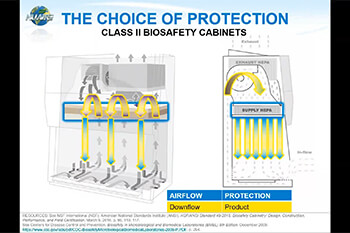

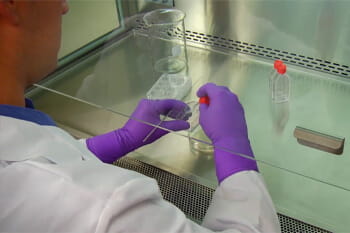

This educational video explains the critical role of high-efficiency particulate Air (HEPA) or ultra-low penetration Air (ULPA) filters used in the supply and exhaust systems of BSCs, which are instrumental in maintaining cleanliness and safety. It introduces viewers to the mechanics behind creating an effective air barrier at the cabinet's front, achieved through an aerodynamic airfoil and a vast access opening. This setup ensures an air inflow rate of 105 feet per minute (0.50 meters per second), establishing a robust barrier against the escape of harmful agents.

Moreover, the video details the HEPEX Zero Leak Airflow System that facilitates true laminar airflow. This system evenly distributes filtered air across the work surface, significantly reducing the risk of cross-contamination. Such features underscore the BSC's ability to provide personnel and environmental protection and product safety by preventing the sample's exposure to contaminants.

The narrative emphasizes that for BSCs to function effectively, proper training in their operation and maintenance is crucial. Laboratory personnel must be well-versed in the correct protocols and adhere to strict guidelines to ensure the cabinets perform optimally, safeguarding against infectious splashes or aerosols. The video is an essential resource for anyone involved in laboratory work, offering insights into the design and functionality of BSCs that are pivotal in maintaining health and safety standards in research and clinical environments.

"Understanding the Biosafety Cabinet" is an invaluable resource for laboratory staff, safety officers, and facility managers, highlighting the indispensable role of BSCs in modern laboratories. By showcasing how these cabinets protect the integrity of scientific work and the well-being of personnel, the video reinforces the need for diligent use, regular maintenance, and compliance with established safety protocols.