PharmaGard NU-PR797 Compounding Aseptic Isolator Restricted Access Barrier System

The NU-PR797 is a Compounding Aseptic Isolator (CAI) that provides a positive pressure environment for compounding sterile, non-hazardous drugs and can be configured for your pharmacy’s workflow.

- Overview

- Specifications

- Reviews

- Resources

- Options

Overview

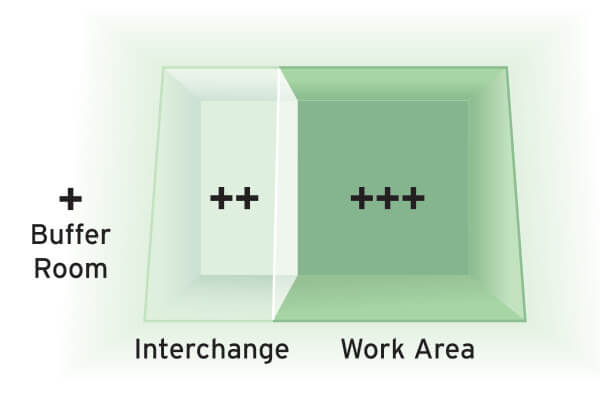

The PharmaGard NU-PR797 is a USP <797> compliant Compounding Aseptic Isolator (CAI) designed for sterile, non-hazardous drug preparation. Boasting a durable stainless-steel structure and a polycarbonate front window equipped with gloves ensures a constant flow of ISO Class 5 HEPA-filtered air at 20 changes per minute. This isolator features a primary work chamber with a higher positive pressure than its adjoining interchange chamber, creating a cascading pressure system that safeguards against interior contamination. Convenient features include a sliding door for material transfer, a hinged front window for easy maintenance, and standard minihelic gauges to monitor chamber pressures. Additionally, the optional PharmaGard™ digital monitor proactively alerts users if the work chamber pressure drops below the desired range.

Counter Balance Inner Transfer Window

The transfer window counter balance is isolated from sterile product inside the inter-chamber wall. The window moves easily up or down with one finger.

Three IV Bar Locations

NuAire RABS comes standard with three IV Bar height locations allowing different pharmacy technicians to comfortably work within the CAI or CACI.

Sliding Work Tray

Located in the transfer compartment, the sliding work tray provides a seamless transition when entering compounding materials into the work zone. The stainless steel work tray is mounted on ball bearing brackets to smoothly enter compounding materials into the sterile work area.

Waste Disposal System

Streamline your waste and sharps disposal process with an integrated system. Designed for maximum sterility and safety, our CAI has two specially designed waste containers accessible through covered drop tubes. This ensures a sterile interior and containment outside. Replacing a full container? It's hassle-free. Each container can be individually swapped out as needed. Plus, with a simple three-step process — release, pull out, and replace — container changes are quick and secure. The PharmaGard Series combines functionality with safety, making your work environment efficient and compliant.

Positive Pressure

Experience superior contamination protection with our compounding aseptic isolator, designed to maintain a consistent positive pressure compared to room conditions. A 45-55 fpm downflow of HEPA-filtered air ensures 20 air changes per minute, delivering an ISO Class 5 environment. The strategic subdivision of the interior offers improved protection for sterile drugs, while the innovative airflow system guarantees the isolator's sustained positive pressure. We are ensuring the utmost drug handling safety where innovation meets contamination-free compounding.

Specifications

| Cord Pass Through | Optional |

| IV Bar with 6 Hooks | One Bar Included, Additional Bar Optional |

| Outlet(s) | One on Back Wall of Work Area |

| Seismic Brackets or Studs | Optional Side, Rear or Floor Mount Seismic Brackets |

| Service Valves (3/8-inch NPT) | N/A |

| Waste/Sharps Disposal System | Optional |

| Construction | Welded stainless steel 16GA, Type 304 pressure tight design |

| Diffuser | Metal, Non-flammable |

| Exhaust Filter | 2-inch (51mm) |

| Glove Ports | Two |

| HEPA Filter Seal Type | Neoprene, Spring-loaded Under Negative Pressure |

| Interchange Chamber | ISO Class 5 With Internal/External Sealed Doors |

| Lighting | Fluorescent |

| Motor(s) | 1 Impeller |

| Style | Bench top, console with optional base stand |

| Supply Filter | 1 11/16-inch (43mm) 99.995% Efficiency @ 0.3 Microns |

| Supply Prefilter | Top of Unit |

| Viewing Window Inches (mm) | Hinged |

| Est. Shipping Depth Inches (mm) | 43 (1092) |

| Est. Shipping Height Inches (mm) | 75 (1905) |

| Est. Shipping Width Inches (mm) | 58 (1474) |

| Exterior Depth Inches (mm) | 32.5 (826) |

| Exterior Height (Minimum with optional base stand) Inches (mm) | 78 (1981) |

| Exterior Height Inches (mm) | 48 (1219) |

| Exterior Width Inches (mm) | 50 (1270) |

| Interchange Interior Depth Inches (mm) | 24 (610) |

| Interchange Interior Height Inches (mm) | 27.375 (695) |

| Interchange Interior Width Inches (mm) | 14.125 (359) |

| Interchange Work Tray Depth Inches (mm) | 17 3/4 (451) |

| Interchange Work Tray Width Inches (mm) | 12 1/2 (318) |

| Work Area Depth Inches (mm) | 23.25 (591) |

| Work Area Height Inches (mm) | 27.375 (695) |

| Work Area Width Inches (mm) | 35.25 (895) |

| Blower/Lights Amps | 3 |

| Electrical Configuration | 115V60Hz |

| Outlet Amps | 3 |

| Power Cord | 14 GA - 3 Wire, 15Amp |

| Power Cord Length Foot (Meter) | 12 (3.7) Hospital Grade |

| Rated Amps | 6 |

| Light Intensity fc (Lux) | 40 - 80 (430 - 860) |

| Sound Pressure Level per ISO 4871 | Inquire |

| Exhaust Requirement CFM (CMH) | N/A |

| Exhaust Requirement for Fixed Canopy (NU-916-797) CFM (CMH) | N/A |

| Plant Duct Static Pressure Inches (mm) | N/A |

| Performance Standard | CETA-CAG-002-2006 |

| Safety Certification | UL, UL-C |

| Air Changes | 20 Air Changes per Minute |

| Air Cleanliness (ISO 14644) | ISO-Class-5 |

| Chamber Pressurization | Positive |

| Downflow fpm (m/s) | 45-55 FPM (0.23 - 0.28 m/s) |

| Heat Rejected (BTU/Hour) | 539 |

| Interchange Pressure | Minimum +0.10" w.g. (0.05" w.g. Less Positive than Work Area) |

| Protection | Product, Personnel, Environmental |

| Work Area Pressure | Minimum +0.15" w.g. |

| Control System | FlowGard |

| PharmaGard Pressure Monitor | Optional |

| Est. Shipping Weight lbs (kg) | 475 (220) |

| Net Weight lbs (kg) | 425 (193) |

| Cord Pass Through | Optional |

| IV Bar with 6 Hooks | One Bar Included, Additional Bar Optional |

| Outlet(s) | One on Back Wall of Work Area |

| Seismic Brackets or Studs | Optional Side, Rear or Floor Mount Seismic Brackets |

| Service Valves (3/8-inch NPT) | N/A |

| Waste/Sharps Disposal System | Optional |

| Construction | Welded stainless steel 16GA, Type 304 pressure tight design |

| Diffuser | Metal, Non-flammable |

| Exhaust Filter | 2-inch (51mm) |

| Glove Ports | Three |

| HEPA Filter Seal Type | Neoprene, Spring-loaded Under Negative Pressure |

| Interchange Chamber | ISO Class 5 With Internal/External Sealed Doors |

| Lighting | Fluorescent |

| Motor(s) | 2 Impellers |

| Style | Bench top, console with optional base stand |

| Supply Filter | 1 11/16-inch (43mm) 99.995% Efficiency @ 0.3 Microns |

| Supply Prefilter | Top of Unit |

| Viewing Window Inches (mm) | Hinged |

| Est. Shipping Depth Inches (mm) | 42 (1067) |

| Est. Shipping Height Inches (mm) | 75 (1905) |

| Est. Shipping Width Inches (mm) | 82 (2083) |

| Exterior Depth Inches (mm) | 32.5 (926) |

| Exterior Height (Minimum with optional base stand) Inches (mm) | 78 (1981) |

| Exterior Height Inches (mm) | 48 (1219) |

| Exterior Width Inches (mm) | 74 (1880) |

| Interchange Interior Depth Inches (mm) | 24 (610) |

| Interchange Interior Height Inches (mm) | 27.375 (695) |

| Interchange Interior Width Inches (mm) | 14.125 (359) |

| Interchange Work Tray Depth Inches (mm) | 17 3/4 (451) |

| Interchange Work Tray Width Inches (mm) | 12 1/2 (318) |

| Work Area Depth Inches (mm) | 23.25 (5891) |

| Work Area Height Inches (mm) | 27.375 (695) |

| Work Area Width Inches (mm) | 59.25 (1505) |

| Blower/Lights Amps | 5 |

| Electrical Configuration | 115V60Hz |

| Outlet Amps | 3 |

| Power Cord | 14 GA - 3 Wire, 15A |

| Power Cord Length Foot (Meter) | 12 (3.7) Hospital Grade |

| Rated Amps | 8 |

| Light Intensity fc (Lux) | 40 - 80 (430 - 860) |

| Sound Pressure Level per ISO 4871 | Inquire |

| Exhaust Requirement CFM (CMH) | N/A |

| Exhaust Requirement for Fixed Canopy (NU-916-797) CFM (CMH) | N/A |

| Plant Duct Static Pressure Inches (mm) | N/A |

| Performance Standard | CETA-CAG-002-2006 |

| Safety Certification | UL, UL-C |

| Air Changes | 20 Air Changes per Minute |

| Air Cleanliness (ISO 14644) | ISO-Class-5 |

| Chamber Pressurization | Positive |

| Downflow fpm (m/s) | 45-55 FPM (0.23 - 0.28 m/s) |

| Heat Rejected (BTU/Hour) | 880 |

| Interchange Pressure | Minimum +0.10" w.g. (0.05" w.g. Less Positive than Work Area) |

| Protection | Product, Personnel, Environmental |

| Work Area Pressure | Minimum +0.15" w.g. |

| Control System | FlowGard |

| PharmaGard Pressure Monitor | Optional |

| Est. Shipping Weight lbs (kg) | 625 (284) |

| Net Weight lbs (kg) | 575 (261) |

Review

Resources

Manuals

Drawings

Specifications

BIM Revit

Request Your Quote for a NU-PR797

Please fill out the form below for a lab equipment quote and we'll get to work on getting you what you need. Need to talk with someone right away? Give us a call at 763-553-1270.

Thank you for completing the form.

We will be in touch. If you have any urgent questions, please reach out at 763-553-1270.