Article

Article

Biosafety Cabinet Classes

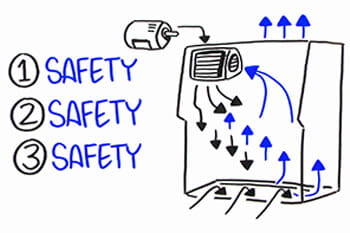

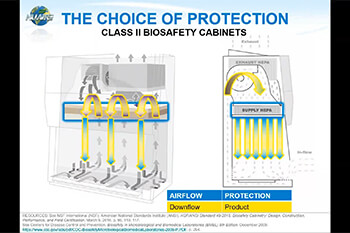

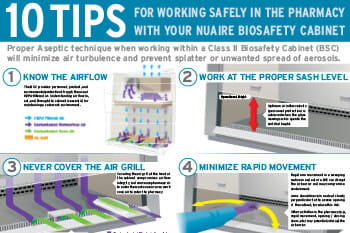

To operate modern healthcare, biomedical, microbiological, chemical, medical research, compounding pharmacy, or pharmaceutical lab, a lab or operations manager should understand the capital equipment employed regularly. The more thorough the knowledge of each device, the more efficiently the lab manager can plan for the implications of deployment, maintenance, repair, and replacement. Most equipment in a laboratory performs an active function. For example, a centrifuge separates liquids, and CO2 incubators grow tissue cultures. In comparison, the role of a biosafety cabinet, while critical, might seem passive. A biosafety cabinet (BSC) does not perform anyone's direct function, but rather it prevents adverse conditions from occurring. BSCs cabinets are meant to prevent harm to employee health and contamination of the environment. Some also prevent contamination of the product in the work zone.

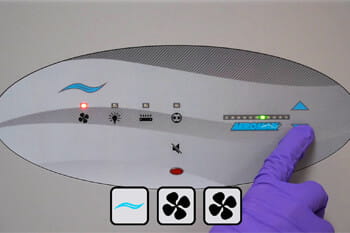

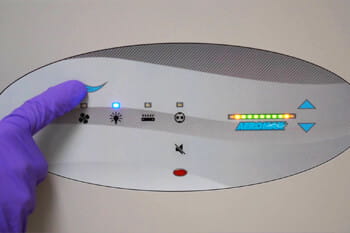

Biosafety Cabinets go by many names; Biological Safety Cabinet, tissue culture hood, and more. Unlike fume hoods, Biosafety cabinets function by causing air to move in precise patterns, as well as filtering air to eliminate particulate matter. This ability requires sophisticated engineering in such areas as the fluid dynamics of airflow, ergonomics of usability, design of the enclosure, and electrical design of motors, blowers, and control systems.

Biosafety Cabinet History

The development of BSCs was a lengthy process, as the 1991 Clinical Microbiology Reviews paper, Biological Safety Cabinetry makes clear.1 The first report of an infection that was the result of exposure to materials in a lab came in 1893. The first survey of a laboratory-acquired disease, typhoid fever, primarily the result of pipette use, began in 1915.

By the middle of the 1900s, the link between laboratory practices and potential contamination and infection was more fully understood. A 1950 survey reported at the annual meeting of the American Public Health Association noted that 5,000 laboratories recorded 1,342 instances of laboratory-acquired infections. Thirty-nine deaths resulted. Of the 1,342 infections, only 467 had previously been made public. This pattern of infection continued in the following decades, as reported by the Centers for Disease Control and Prevention (CDC) and the National Animal Disease Center. Such reports may not have addressed the full scope of harm. Focusing only on human infection may overlook the adverse effects of poor contamination control on the work product of the labs involved. The forerunner of the biosafety cabinet appeared in 1909 when a company offered a ventilated hood to prevent infection with tuberculosis when preparing tuberculin. An enclosed cabinet was first mentioned in the scientific literature in 1943. By the early 1950s, the U.S. Army Biological Laboratories at Fort Detrick, Maryland developed and implemented sophisticated containment cabinet technology.2

The use of containment cabinets began to spread, continuing to the present. Currently, BSCs are considered standard in laboratories to prevent a broad range of potential contaminants.

Although BSCs must provide safety for personnel and improved accuracy in testing and production through controlling airborne contamination, the terms “safety” and “control of airborne contamination” are relative terms. Is there an acceptable degree of exposure in a particular instance? Does a standard exist by which the effectiveness of BSCs from different manufactures can be measured?

For those reasons and others, NSF International, a standards development organization, created standard NSF/ANSI 49 that classifies BSCs into classes and types based upon the performance and protection each must meet. Another core standard similar to NSF/ANSI 49 is the European standard EN12469 for Microbiological Safety Cabinets (MBSC), another term for BSC, that determines similar criteria a BSC must meet. What satisfies the needs of one lab might be overkill or insufficient for another. Minimum standards allow lab managers and safety officers to know, at the very least, what they can count on. To understand BSCs in light of a lab’s safety requirements, an extended look at BSCs is necessary.